Table of Contents

Understanding Robotic Systems Integration and Automated Inspection

Benefits of Robotic Systems Integration and Automated Inspection

Applications of Robotic Systems Integration and Automated Inspection

Overcoming Challenges in Robotic Systems Integration and Inspection

MTL 3D’s Solutions for Robotic Systems Integration and Automated Inspection

The Future of Robotic Systems Integration and Automated Inspection

Conclusion: Shaping the Manufacturing Landscape with Robotics and Inspection

Understanding Robotic Systems Integration and Automated Inspection

What Is Robotic Systems Integration?

Robotic systems integration is the process of merging various robotic components—such as arms, sensors, vision systems, and software—into a unified workflow. This process ensures seamless communication between hardware and software, enabling robots to execute tasks like material handling, grinding, inspection, and assembly efficiently and accurately.

For example: In aerospace manufacturing, where tolerances are measured in microns, robotic systems are crucial for handling complex geometries like turbine blades and IBRs, ensuring consistency, accuracy, and repeatability.

The Role of Automated Inspection in Modern Manufacturing

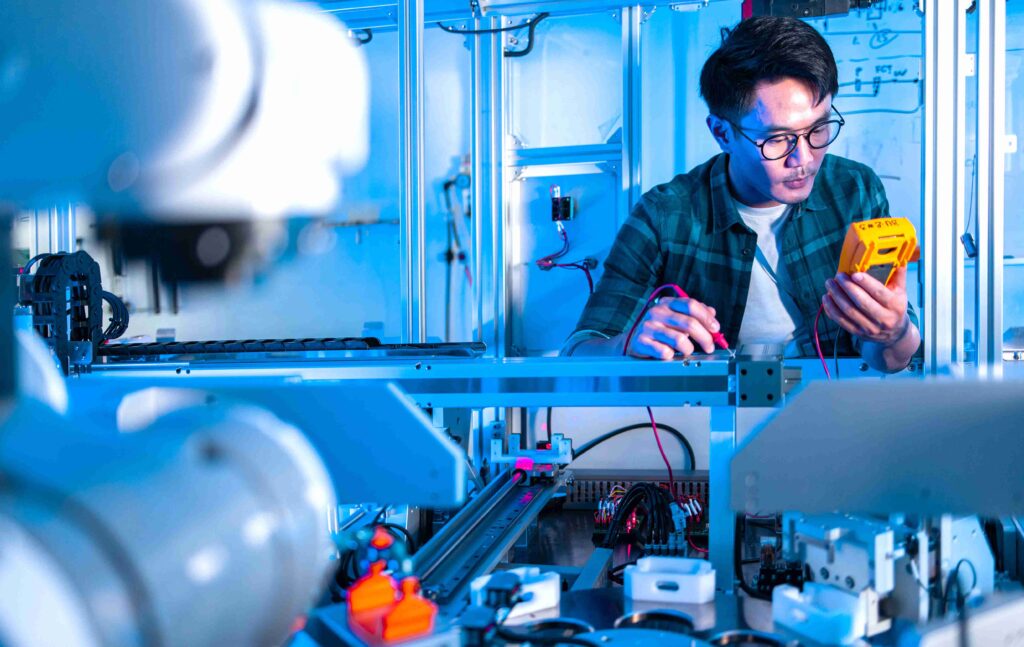

Automated inspection technologies use robotics, advanced sensors, and vision systems to evaluate product quality, detect defects, and ensure compliance with stringent standards. By eliminating the need for manual inspections, these systems increase accuracy, reduce waste, and accelerate production timelines.

Example: MTL 3D’s Blazer Systems leverage non-contact inspection methods to deliver precise measurements for aerospace and defense components. This ensures that even the smallest flaws are identified before they escalate into costly issues.

Challenges in Robotic Systems Integration and Inspection

Complexity in Configuring Robotic Systems

Integrating robotic systems requires careful alignment of hardware, software, and workflows. Programming robotic arms, synchronizing them with inspection systems, and managing communication between components can be highly complex. Without proper configuration, these systems risk inefficiencies and downtime.

Interoperability Challenges in Robotic Inspection Systems

Inspection systems often operate on proprietary software or protocols, which makes communication with other robotic components challenging. When data cannot seamlessly flow between inspection and production systems, manufacturers face bottlenecks that disrupt operations.

Addressing the Lack of Standardization Across Platforms

The absence of universal standards in robotics adds another layer of complexity. Integrating solutions from multiple vendors often requires custom engineering, which can be both costly and time-consuming. MTL 3D addresses this challenge by developing adaptable systems that integrate seamlessly into existing workflows.

Benefits of Robotic Systems Integration and Automated Inspection

Enhanced Efficiency Through Integrated Robotics

When robotic systems work together seamlessly, they streamline production processes, handle repetitive tasks like grinding or assembly with precision, and significantly reduce downtime.

Example: With MTL 3D’s RoboMate Systems, grinding cycles are reduced by 60–70%, enabling manufacturers to meet production deadlines more efficiently.

Improved Quality Assurance with Automated Inspection

Non-contact inspection systems like Blazer Systems ensure compliance with strict quality standards by detecting deviations in real time. Automated corrective actions minimize waste and ensure that only flawless products move forward.

Flexibility and Scalability with Robotic Integration

Integrated robotic systems offer the flexibility to adapt to changing production requirements, whether scaling up for higher demand or switching between products with minimal retooling.

Reducing Risks and Ensuring Workforce Safety

By automating hazardous tasks, robotic systems reduce risks to human workers. Vision-equipped robots can operate in extreme environments or handle dangerous materials, ensuring a safer workplace.

Applications of Robotic Systems Integration and Automated Inspection

Aerospace and Defense Robotics for Precision Inspection

In aerospace, where safety and precision are paramount, robotic systems equipped with non-contact inspection technologies are critical. They inspect turbine blades, fuselage panels, and IBRs to ensure structural integrity and compliance with vendor-specific requirements.

Electronics Manufacturing and Inspection Automation

In electronics, robotic systems can handle delicate components like circuit boards and microchips with precision. Vision-based inspection ensures that every connection meets quality standards, preventing costly errors.

Overcoming Challenges in Robotic Systems Integration and Inspection

The Development of Modular Robotic Components

Modularity simplifies integration by allowing manufacturers to swap or upgrade components without overhauling the entire system. This reduces costs and ensures long-term adaptability.

Leveraging AI and IoT for Smarter Robotic Inspection

MTL 3D is exploring ways to integrate AI and IoT into its systems to enhance real-time defect detection, predictive maintenance, and dynamic process optimization.

MTL 3D’s Solutions for Robotic Systems Integration and Automated Inspection

Blazer Systems: Precision in Non-Contact Inspection

Blazer Systems deliver high-speed, non-contact inspection tailored to industries like aerospace.

Faster Inspections: Reduce inspection times by 55%.

Real-Time Data Integration: Ensures instant defect identification and reporting.

RoboMate Systems: Advancing Robotic Grinding and Polishing

RoboMate combines grinding, polishing, and inspection into a single automated system.

Efficiency Gains: Reduces grinding cycles by 60–70%.

Seamless Integration: Works with Blazer Systems to optimize workflows.

MTL 3D Software: Intuitive Control and Analysis

User-Friendly Design: Guides operators step-by-step, simplifying operation.

Custom Reports: Tailored for traceability and compliance needs.

By integrating MTL 3D’s products into your manufacturing processes, you can achieve superior robotic systems integration and automated inspection, leading to enhanced precision, efficiency, and overall operational excellence.

The Future of Robotic Systems Integration and Automated Inspection

Fully Autonomous Factories with Integrated Inspection

MTL 3D envisions factories where robotics and inspection systems operate in harmony, synchronizing production and quality assurance in real time.

Using Predictive Analytics for Proactive Quality Management

Future systems will leverage predictive analytics to anticipate defects, ensuring proactive quality control and minimizing downtime.

Conclusion: Shaping the Manufacturing Landscape with Robotics and Inspection

Robotic systems integration and automated inspection are no longer optional—they’re essential for manufacturers aiming to stay competitive. With innovative solutions like Blazer Systems, RoboMate, and intuitive software, MTL 3D is helping industries redefine precision, efficiency, and safety. By embracing these advancements, manufacturers can unlock unparalleled levels of performance, paving the way for a smarter, more sustainable future.

Explore how MTL 3D can enhance your manufacturing processes at www.mtl-3d.com.

#roboticsystemsintegration #automatedinspection #mtl3d