Introduction to Inspection Technology

Inspection technology has come a long way from the days of manual tools and visual checks. In fact, studies show that the global non-destructive testing market, which includes inspection technology, is expected to reach $17.9 billion by 2025, reflecting its increasing importance across industries. With advances in automation, precision engineering, and data management, industries are now embracing cutting-edge solutions to enhance safety, efficiency, and decision-making. From Blazer Systems to custom inspection platforms, today’s tools redefine how industries approach quality control.

In this piece, we’ll explore the latest trends in inspection technology and how they’re reshaping industries like aerospace manufacturing and precision engineering. These advancements provide not only improved inspection data but also the ability to optimize workflows and make smarter manufacturing decisions.

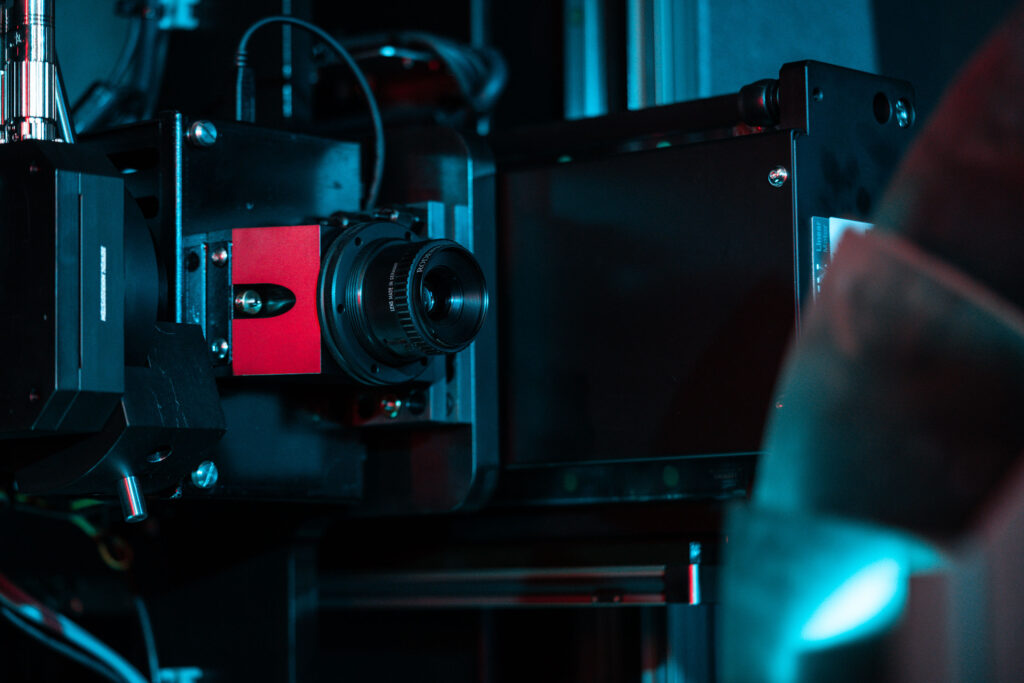

Advancements in Camera Technology for Inspection

One of the biggest leaps in inspection technology has been in cameras. High-resolution and 360-degree cameras now allow for detailed visual inspections in areas that were previously inaccessible. Infrared and thermal imaging add another layer of precision, making it easier to identify issues like heat loss or structural flaws.

Take our MTL 3D Blazer Systems, for example. Their advanced non-contact inspection cameras can capture inspection data with unparalleled clarity, ensuring that every detail is accounted for. This level of precision is especially critical in aerospace manufacturing, where even the smallest defect can have significant consequences.

In addition to high-resolution imaging, cameras are now being integrated with advanced software that can process inspection data in real-time. These systems are capable of identifying trends and patterns that might otherwise go unnoticed, contributing to better manufacturing decisions. Industries are also beginning to leverage cameras equipped with AI, enabling these systems to learn and improve over time.

In this piece, we’ll explore the latest trends in inspection technology and how they’re reshaping industries like aerospace manufacturing and precision engineering. These advancements provide not only improved inspection data but also the ability to optimize workflows and make smarter manufacturing decisions.

AI and Machine Learning in Inspection Technology

Artificial intelligence (AI) and machine learning are transforming the inspection industry by automating defect detection and providing predictive analytics. These technologies analyze inspection data in real-time, offering actionable insights to optimize manufacturing decisions.

Imagine an inspection system that doesn’t just identify a defect but predicts when and where similar issues might arise in the future. This proactive approach to quality control is what sets today’s inspection technology apart. By integrating AI, industries can achieve workflow optimization and make data-driven manufacturing decisions.

Custom inspection platforms now frequently include machine learning algorithms that can adapt to specific operational needs. For example, in aerospace manufacturing, AI-powered inspection systems can analyze wear and tear on components, suggesting maintenance schedules that prevent costly failures. Additionally, machine learning is proving invaluable in precision engineering, where even the smallest discrepancies can impact product quality.

Take our MTL 3D Blazer Systems, for example. Their advanced non-contact inspection cameras can capture inspection data with unparalleled clarity, ensuring that every detail is accounted for. This level of precision is especially critical in aerospace manufacturing, where even the smallest defect can have significant consequences.

In addition to high-resolution imaging, cameras are now being integrated with advanced software that can process inspection data in real-time. These systems are capable of identifying trends and patterns that might otherwise go unnoticed, contributing to better manufacturing decisions. Industries are also beginning to leverage cameras equipped with AI, enabling these systems to learn and improve over time.

In this piece, we’ll explore the latest trends in inspection technology and how they’re reshaping industries like aerospace manufacturing and precision engineering. These advancements provide not only improved inspection data but also the ability to optimize workflows and make smarter manufacturing decisions.

Robotics and Drones in Inspection Technology

Robotic solutions and drones are becoming essential tools in the inspection world. They offer unparalleled access to hazardous or hard-to-reach areas, reducing the need for human intervention.

For instance, robotic crawlers equipped with cameras and sensors can navigate pipelines and other confined spaces. Drones, on the other hand, excel in aerial inspections, making them perfect for large infrastructure projects or even aerospace manufacturing facilities. These robotic solutions enhance efficiency and safety, allowing for thorough inspections without compromising the workforce.

Beyond their physical capabilities, robotic solutions are now being integrated with advanced inspection systems. These systems combine robotics with AI to create automated workflows that further improve accuracy and efficiency. Whether it’s inspecting the structural integrity of a bridge or analyzing the surface of a spacecraft, robotic inspection systems are paving the way for a new standard in precision engineering.

In this piece, we’ll explore the latest trends in inspection technology and how they’re reshaping industries like aerospace manufacturing and precision engineering. These advancements provide not only improved inspection data but also the ability to optimize workflows and make smarter manufacturing decisions.

Cloud Computing and Data Management in Inspection Technology

Gone are the days of paper-based logs and manual data entry. Modern inspection systems now rely on cloud computing to store and analyze inspection data securely. This not only ensures real-time access but also improves collaboration among teams.

When inspection data is centralized in the cloud, it streamlines decision-making processes. Workflow optimization becomes effortless as teams can instantly share findings, compare results, and implement changes across multiple locations. For industries like aerospace manufacturing, where precision and timely decisions are critical, this level of connectivity is a game-changer.

Cloud computing also plays a significant role in facilitating remote inspections. Inspectors can access live feeds and data from drones, robots, or other inspection systems without being physically present at the site. This approach not only saves time and resources but also enhances safety by reducing the need for on-site personnel.

For instance, robotic crawlers equipped with cameras and sensors can navigate pipelines and other confined spaces. Drones, on the other hand, excel in aerial inspections, making them perfect for large infrastructure projects or even aerospace manufacturing facilities. These robotic solutions enhance efficiency and safety, allowing for thorough inspections without compromising the workforce.

Beyond their physical capabilities, robotic solutions are now being integrated with advanced inspection systems. These systems combine robotics with AI to create automated workflows that further improve accuracy and efficiency. Whether it’s inspecting the structural integrity of a bridge or analyzing the surface of a spacecraft, robotic inspection systems are paving the way for a new standard in precision engineering.

In this piece, we’ll explore the latest trends in inspection technology and how they’re reshaping industries like aerospace manufacturing and precision engineering. These advancements provide not only improved inspection data but also the ability to optimize workflows and make smarter manufacturing decisions.

Augmented and Virtual Reality in Inspection Technology

Virtual and augmented reality are making waves in the inspection industry. Virtual reality (VR) is primarily used for training inspectors, offering realistic simulations of inspection scenarios without the need for on-site practice. This is particularly beneficial for industries like precision engineering and aerospace manufacturing, where training can be both time-consuming and expensive.

Augmented reality (AR) takes things a step further by overlaying digital information onto real-world environments. Picture an inspector using AR glasses to view a machine’s internal components and instantly identifying areas requiring maintenance. This integration of AR in custom inspection processes is a game-changer for efficiency and accuracy.

AR and VR technologies are also enhancing how inspection data is visualized. Instead of sifting through complex spreadsheets, inspectors can now interact with 3D models that provide a comprehensive view of the inspection site. This approach not only improves understanding but also speeds up decision-making.

IoT Connectivity and Smart Devices in Inspection Technology

The Internet of Things (IoT) has brought about a new era of connected devices. Smart inspection systems now include sensors that provide real-time monitoring and instant alerts. This IoT-enabled connectivity ensures that no issue goes unnoticed.

In manufacturing environments, IoT devices can integrate with broader inspection systems to offer a comprehensive overview. This level of automation not only improves accuracy but also reduces downtime, allowing for seamless manufacturing decisions. For example, sensors embedded in machinery can detect temperature fluctuations or vibrations, triggering automated inspections before a failure occurs.

Augmented reality (AR) takes things a step further by overlaying digital information onto real-world environments. Picture an inspector using AR glasses to view a machine’s internal components and instantly identifying areas requiring maintenance. This integration of AR in custom inspection processes is a game-changer for efficiency and accuracy.

AR and VR technologies are also enhancing how inspection data is visualized. Instead of sifting through complex spreadsheets, inspectors can now interact with 3D models that provide a comprehensive view of the inspection site. This approach not only improves understanding but also speeds up decision-making.

Sustainable Practices in Inspection Technology

Sustainability is more than a buzzword; it’s a necessity. Inspection technology is playing a significant role in promoting eco-friendly practices. By identifying areas for energy efficiency improvements, these systems help reduce waste and minimize environmental impact.

Non-contact inspection methods, such as those used by Blazer Systems, are particularly noteworthy. They eliminate the need for invasive procedures, preserving the integrity of materials while achieving precision. This aligns perfectly with the sustainability goals of industries like aerospace manufacturing and precision engineering.

The use of sustainable materials in the development of inspection technology is also gaining traction. Many companies are now prioritizing eco-friendly components in their devices, ensuring that the tools themselves align with broader environmental goals.

In manufacturing environments, IoT devices can integrate with broader inspection systems to offer a comprehensive overview. This level of automation not only improves accuracy but also reduces downtime, allowing for seamless manufacturing decisions. For example, sensors embedded in machinery can detect temperature fluctuations or vibrations, triggering automated inspections before a failure occurs.

Augmented reality (AR) takes things a step further by overlaying digital information onto real-world environments. Picture an inspector using AR glasses to view a machine’s internal components and instantly identifying areas requiring maintenance. This integration of AR in custom inspection processes is a game-changer for efficiency and accuracy.

AR and VR technologies are also enhancing how inspection data is visualized. Instead of sifting through complex spreadsheets, inspectors can now interact with 3D models that provide a comprehensive view of the inspection site. This approach not only improves understanding but also speeds up decision-making.

Case Studies of Inspection Technology Integration

Real-world examples highlight the transformative power of modern inspection technology. One such example is the use of the ‘NoMan’ camera for tank inspections. This high-performance device eliminates the need for human entry into hazardous environments, ensuring safety while delivering high-quality inspection data.

Another example is the integration of drones in large-structure maintenance. By combining drones with AI-powered inspection systems, teams can identify structural defects quickly and efficiently, enhancing overall project outcomes.

The aerospace industry provides additional case studies where custom inspection systems have prevented critical failures. From detecting hairline cracks in aircraft fuselages to monitoring the wear on turbine blades, these technologies demonstrate the value of precision engineering in maintaining safety and performance.

Challenges and Future Directions in Inspection Technology

While the advancements are impressive, there are challenges to overcome. High implementation costs and the need for specialized training can be barriers to adoption. Additionally, ensuring the interoperability of different inspection systems remains a critical focus.

Looking ahead, the future of inspection technology will likely involve even greater automation, smarter AI algorithms, and more sustainable solutions. Industries must embrace these innovations to remain competitive and ensure long-term success. Collaboration among technology providers, such as Blazer Systems, and end-users will be essential to drive further advancements.

MTL 3D: Transforming Inspection Technology

MTL 3D is at the forefront of revolutionizing inspection technology, offering a suite of advanced products designed to meet the rigorous demands of modern industries. Our offerings include the Blazer Systems, RoboMate Systems, and MTL 3D Software, each engineered to enhance precision, efficiency, and adaptability in quality control processes.

Blazer Systems

Our Blazer Systems are renowned for their high precision, delivering accurate measurements essential for industries with strict quality standards. These systems are fully automated, minimizing human error and improving efficiency. Optimized for high-speed operations, Blazer Systems enhance processing speed and overall productivity. Their flexibility allows them to handle various geometries, making them versatile for different applications. Advanced software integration supports real-time monitoring, data analysis, and process optimization, ensuring seamless operation within your existing workflows.

RoboMate Systems

The RoboMate Systems are designed for adaptability, featuring high-accuracy sensors and edge measurement units that ensure quality control with minimal cycles of grinding. They offer full compatibility, seamlessly integrating with Blazer Systems to ensure smooth operation and quick adaptation. These systems facilitate rapid processing with reduced rejection rates, boosting overall productivity. By leveraging advanced algorithms, RoboMate optimizes grinding and polishing processes, seamlessly guided by Blazer inspection data.

MTL 3D Software

Our intuitive, user-friendly software leads operators step-by-step through smart parameter inputs. It offers a variety of inspection methods and provides both standard and customized inspection reports. The software includes a graphic display of excess material, aiding in precise quality assessments and decision-making processes. Request a Demo and see how MTL 3D’s advanced solutions can help your manufacturing capabilities.

Conclusion: The Evolution of Inspection Technology

Inspection technology is no longer just a tool but a comprehensive ecosystem of robotics, AI, IoT connectivity, and sustainable practices. From the remarkable capabilities of Blazer Systems’ non-contact solutions to the integration of IoT devices and cloud computing, the industry has entered a new era of precision, efficiency, and environmental responsibility.

Industries like aerospace manufacturing, precision engineering, and large-scale infrastructure maintenance are reaping the benefits of these advancements. By leveraging AI for predictive maintenance, AR for real-time assistance, and robotics for hazardous inspections, companies can enhance safety while achieving workflow optimization.

As we look to the future, it’s clear that inspection technology will continue to evolve, addressing challenges like high costs and system interoperability. These innovations promise not only to meet today’s demands but to set the stage for a safer, more efficient, and sustainable tomorrow. For businesses committed to excellence, staying ahead in inspection technology isn’t just advisable—it’s essential for success.

And staying ahead is more than essential, it’s required. Learn how MTL 3D can help you and your manufacturing inspection capabilities. Contact us today and speak to one of our MTL 3D team members, today.