Table of Contents

- Introduction to Industrial Metrology

- The Evolution of Metrology in Manufacturing

- Understanding 3D Metrology: The Future of Precision

- The Five Fundamental Elements of Metrology

- How MTL 3D Innovates in Industrial Metrology

- Industry Applications of MTL 3D’s Solutions

- Advanced Automation Solutions for Quality Control Systems

- The Future of Industrial Metrology and MTL 3D’s Vision

- Conclusion

Introduction to Industrial Metrology

Industrial metrology is the backbone of manufacturing and production, ensuring accuracy, precision, and reliability. It involves using advanced measurement techniques to verify product quality and align manufacturing processes with stringent standards.

At MTL 3D Ltd., we specialize in transforming industrial metrology through innovative technologies, including non-contact inspection systems, robotics, and intelligent software solutions. Our mission is simple: to empower industries with tools that enhance efficiency, improve quality control, and reduce costs.

The Evolution of Metrology in Manufacturing

Metrology has evolved significantly over the decades, from manual tools like calipers and micrometers to sophisticated automated systems. Key milestones in this journey include:

- 1920s: The invention of measuring microscopes, revolutionizing the inspection of small components.

- 1970s: The introduction of CNC coordinate measuring machines (CMMs) automated the process, increasing precision and speed.

- 2000s and Beyond: Technologies like laser scanning, structured light, and robotics have taken metrology to new heights.

MTL 3D builds on these advancements with systems that integrate seamlessly into modern production lines, providing unparalleled accuracy and efficiency.

Understanding 3D Metrology: The Future of Precision

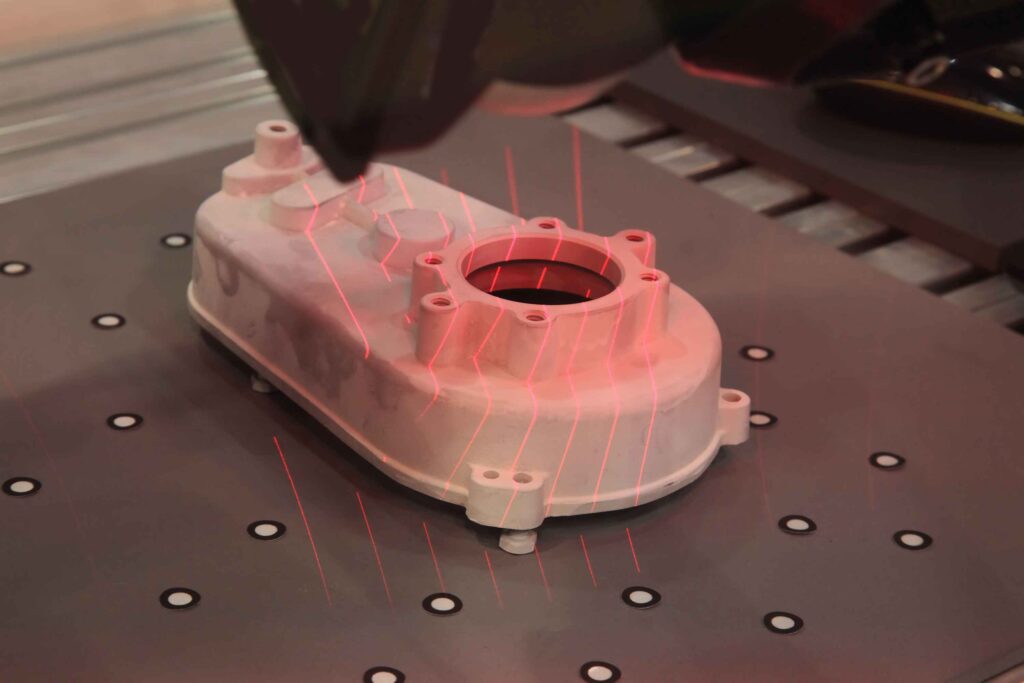

3D metrology measures objects across three axes—x, y, and z—to create detailed geometrical data. This technology has become indispensable in industries requiring precise measurements of complex parts.

Core Technologies in 3D Metrology

- Laser Scanning: Captures detailed surface data at high speeds.

- Structured Light: Projects patterns onto surfaces to measure variations.

- Coordinate Measuring Machines (CMMs): Uses tactile probes for ultra-precise measurements.

- Computed Tomography (CT): Provides internal and external measurements.

These methods enable manufacturers to optimize production, reduce errors, and ensure compliance with industry standards. MTL 3D’s Blazer Systems and RoboMate Systems incorporate these technologies to deliver top-tier performance.

The Five Fundamental Elements of Metrology

A robust metrology system includes these essential elements:

- Sensors: Detect physical properties for measurement.

- Conversion Mechanisms: Transform raw data into usable formats.

- Data Processing Units: Enhance the accuracy and usability of data.

- Transmission Systems: Facilitate seamless data flow.

- Presentation Interfaces: Provide intuitive and actionable outputs.

MTL 3D integrates these elements into every product, ensuring reliable and user-friendly operation.

How MTL 3D Innovates in Industrial Metrology

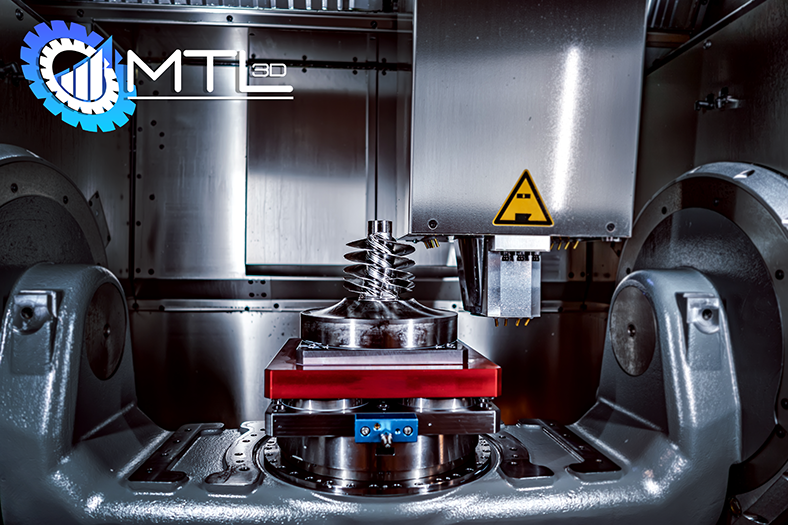

Blazer Systems: Precision Redefined

The Blazer Systems are fully automated inspection solutions designed for high-speed operations.

Key Features:

- High-resolution laser sensors for accurate measurements.

- Real-time defect detection and reporting.

- Versatility to handle various part geometries.

These systems are perfect for industries that demand consistent quality, from aerospace to automotive.

RoboMate Systems: Automated Excellence

RoboMate Systems combine advanced robotics with precision metrology to deliver unmatched accuracy.

Applications:

- Free-form part inspection.

- High-speed quality checks.

- Reduced waste through early defect detection.

The adaptability of RoboMate ensures smooth integration into existing workflows.

MTL 3D Software: Intuitive Inspection Solutions

Our proprietary software simplifies the inspection process with features like:

- Smart inputs for automated operations.

- Detailed graphical reports highlighting deviations.

- Compatibility with multiple metrology systems.

This software empowers operators to make informed decisions quickly and effectively.

Industry Applications of MTL 3D’s Solutions

Aerospace: Pushing the Limits of Accuracy

Precision is critical in aerospace, where even minor deviations can lead to catastrophic failures. MTL 3D’s systems ensure that every component meets exacting standards, enhancing safety and performance.

Automotive: Streamlining Production Lines

Automotive manufacturing demands speed and consistency. With Blazer Systems and RoboMate Systems, MTL 3D helps automotive companies maintain quality while optimizing production efficiency.

Defense: Precision for Mission-Critical Operations

In the defense sector, precision and reliability are paramount. Components used in military equipment, from aircraft and naval systems to advanced weaponry, must meet the highest standards of accuracy to ensure operational effectiveness and safety.

How MTL 3D Supports Defense Applications:

- Non-Contact Inspection for Sensitive Components: Ensures accurate measurements without risking damage to delicate or complex parts.

- High-Speed Quality Control: Reduces production timelines while maintaining uncompromising standards.

- Advanced Reporting Capabilities: Provides detailed insights to meet stringent regulatory and performance requirements.

MTL 3D’s solutions enable defense manufacturers to produce equipment that performs flawlessly under the most demanding conditions, ensuring readiness and reliability in critical missions.

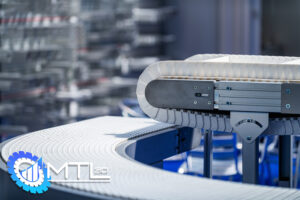

Advanced Automation Solutions for Quality Control Systems

Automation is transforming quality control, and MTL 3D is at the forefront of this revolution.

How Automation Enhances Quality Control

- Eliminates Human Error: Automated systems provide consistent results.

- Increases Productivity: Faster inspection times mean higher throughput.

- Reduces Costs: Early defect detection minimizes waste.

By integrating advanced robotics, intelligent software, and high-precision sensors, MTL 3D delivers automation solutions that redefine quality control.

The Future of Industrial Metrology and MTL 3D’s Vision

As industries adopt smart manufacturing practices, the role of metrology will expand. Trends shaping the future include:

- AI Integration: Artificial intelligence will enhance data analysis and predictive maintenance.

- Digital Twins: Real-time 3D models will enable virtual inspections and simulations.

- Sustainability: Metrology will play a key role in reducing material waste and improving energy efficiency.

MTL 3D is committed to staying ahead of these trends, continually innovating to meet the evolving needs of global industries.

Conclusion

Industrial metrology is more than a technical discipline; it’s a vital enabler of modern manufacturing. At MTL 3D Ltd., we take pride in offering solutions that combine precision, speed, and automation to help industries achieve their goals.

From our Blazer Systems and RoboMate Systems to our intuitive software, we provide tools that enhance quality control, streamline production, and reduce costs. As the industry evolves, MTL 3D remains committed to leading the way with cutting-edge technologies and unparalleled expertise.

To learn more about how MTL 3D can transform your operations, visit our products page.