Table of Contents:

- Introduction to Quality Control Challenges

- How Industrial Automation Improves Quality Control

- Meet MTL 3D: Innovating Quality Control With A Automation

- Real-World Applications: MTL 3D in Action

- Key Features of MTL 3D’s Automation Solutions

- Industries Benefiting from MTL 3D

- Future Trends in Industrial Automation

- Transform Your Quality Control Today

Introduction to Quality Control Challenges

Manufacturers today face intense pressure to meet high-quality standards while maintaining efficiency and cost-effectiveness. Quality control (QC) plays a crucial role in ensuring customer satisfaction, meeting regulatory requirements, and avoiding costly recalls or downtime. However, many companies still rely on outdated, manual methods that cannot keep up with modern production demands.

Key Challenges in Traditional QC:

In today’s manufacturing landscape, maintaining consistent product quality while balancing efficiency and cost is critical. Traditional quality control (QC) methods, however, often fall short, leading to defects, inefficiencies, and compliance risks.

Common Challenges in QC:

- Human Error: Manual inspections are prone to mistakes, leading to undetected defects.

- Inefficiency: Outdated systems slow down production and create bottlenecks.

- High Costs: Rework, product recalls, and wasted materials increase operational expenses.

- Compliance Risks: Failing to meet industry standards can result in lost business opportunities or penalties.

Industries like aerospace, automotive, heavy machinery, and defense face these challenges acutely, as precision and safety are paramount. The solution lies in adopting advanced QC methods driven by automation and innovation.

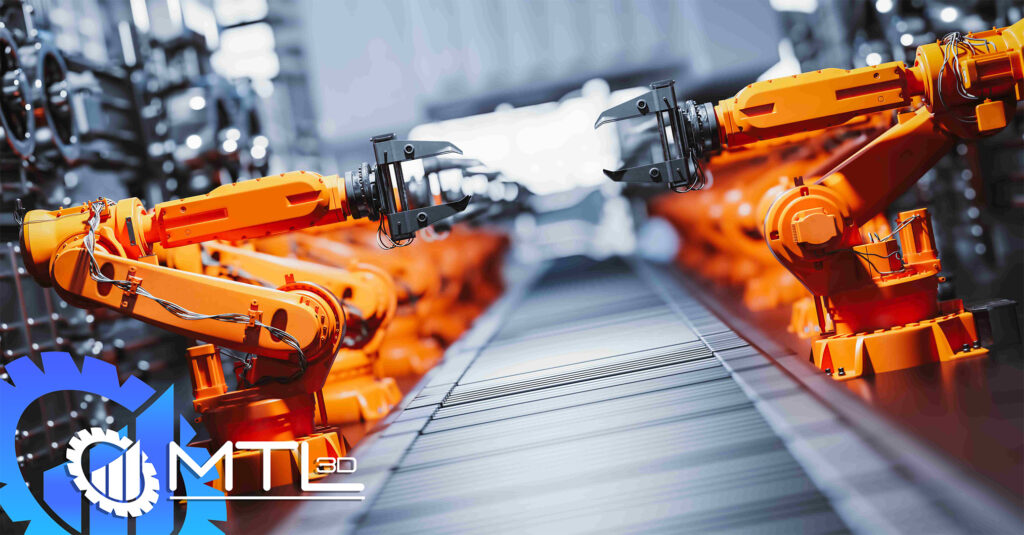

How Industrial Automation Improves Quality Control

Industrial automation has reshaped the manufacturing process, offering tools that transform QC from a reactive task to a proactive strategy. By integrating robotics, 3D scanning, and advanced control systems, manufacturers can achieve unparalleled precision and efficiency.

Key Benefits of Automated QC:

- Unmatched Accuracy: Detect microscopic flaws invisible to human inspectors.

- Faster Processes: High-speed inspections reduce production time.

- Real-Time Data: Automation provides instant feedback to address issues promptly.

- Cost Savings: Minimize rework, downtime, and resource waste.

- Compliance Assurance: Meet rigorous industry standards with confidence.

Automation not only solves today’s challenges but also prepares businesses for future demands.

Meet MTL 3D: Innovating Quality Control with Automation

MTL 3D specializes in creating tailored industrial automation solutions that address complex QC challenges. By blending technological expertise with deep industry knowledge, MTL 3D ensures manufacturers can achieve consistent results and stay ahead in competitive markets.

Why Choose MTL 3D:

MTL 3D brings 25 years of experience in delivering high-quality inspection solutions and developing high-speed industrial inspection systems. Our expertise spans multiple sectors, including aviation, defense, and automotive, with a focus on solving complex manufacturing challenges.

Key Reasons to Partner with MTL 3D:

- Tailored Solutions: Each system is customized to meet specific operational and industry requirements.

- Proven Expertise: Over two decades of experience in designing and implementing innovative solutions for quality control and inspection.

- Blazer Trademark Systems:

- Non-contact, short cycle time systems designed for industrial environments.

- Specifically engineered for inspecting aero engine blades for the aviation sector and other complex geometries in defense and automotive industries.

- Trusted and proven in leading facilities such as Blades Technologies (Pratt & Whitney Israel), GE Singapore, and PCI in the USA.

- Sector-Specific Knowledge: Deep understanding of the needs and standards in aerospace, automotive, heavy machinery, and defense industries.

- Scalable and Reliable: Systems designed to integrate seamlessly into production lines and adapt to future technological advancements.

- Global Reach and Impact: Successfully implemented solutions in leading organizations across the world.

By combining technological innovation with practical expertise, MTL 3D consistently delivers systems that improve efficiency, ensure compliance, and maintain the highest standards of precision.

Real-World Applications: MTL 3D in Action

1. RoboMate: Robotic Adaptive Grinding Cell for Turbine Blades

MTL 3D designed and implemented a fully automated grinding cell as the final stage in aero engine blade manufacturing.

Highlights:

- Utilizes multiple grinding tools to handle intricate blade geometries.

- In-process inspection ensures quality control during production.

- Fully automated, reducing manual intervention while maintaining precision.

Outcome:

This system enhances production consistency, accelerates lead times, and ensures every processed part meets the highest specifications.

2. Automatic Coating System for Turbine Blade Blanks

This automated solution coats turbine blade blanks at critical stages of manufacturing to prepare them for the forging process.

Highlights:

- Ensures precise and consistent coating application.

- Handles various part sizes and geometries seamlessly.

- Fully automated, reducing labor costs and ensuring quality.

Outcome:

The system enhances material integrity during forging, reducing defects and improving overall durability.

3. Robotic Sorting Solutions for Blazer Inspection Systems

A robotic sorting system developed for aero engine blade manufacturing, integrated with MTL 3D’s Blazer inspection systems.

Highlights:

- Automatically sorts inspected parts based on results and deviations from nominal values.

- Adapts to changing production requirements with minimal setup adjustments.

- Fully autonomous, improving efficiency and reducing human error.

Outcome:

This solution optimizes post-inspection workflows, streamlining production and ensuring accurate sorting for complex manufacturing processes.

Key Features of MTL 3D’s Industrial Automation Solutions

1. 3D Scanning for Precision

MTL 3D employs cutting-edge 3D scanning to deliver precise inspections, capturing even the smallest deviations.

Advantages:

- Microscopic defect detection.

- Real-time batch inspections for enhanced productivity.

- Adaptable to diverse shapes and sizes, from small components to large assemblies.

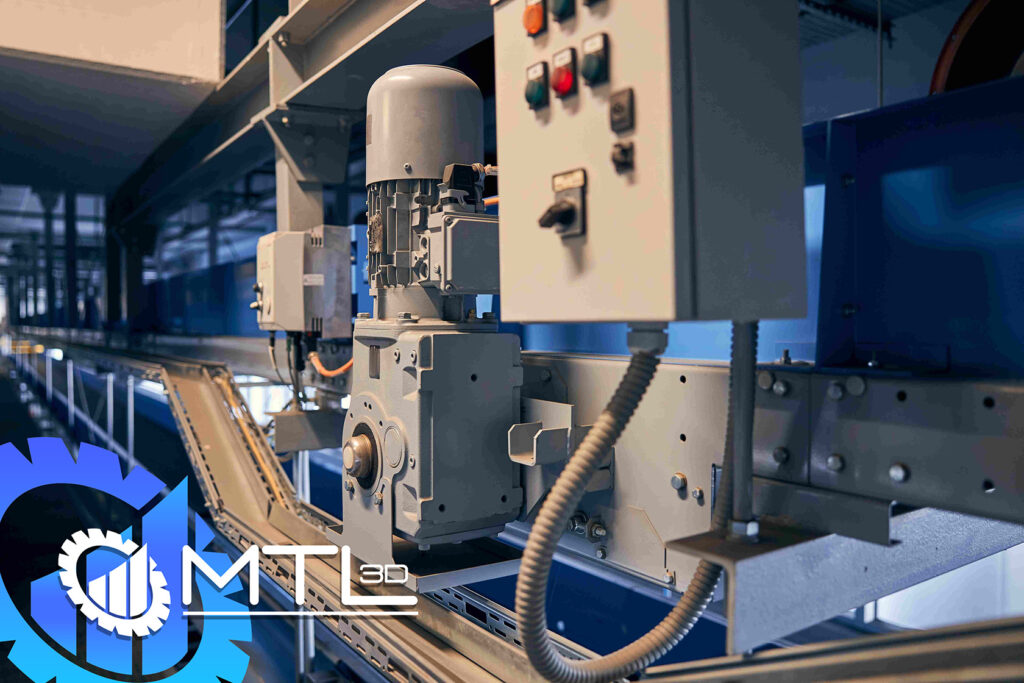

2. Customizable Integration

MTL 3D ensures seamless integration with existing systems, minimizing downtime and disruption.

Features:

- Compatibility with ERP and MES systems.

- Scalable to grow with your operations.

- User-friendly interfaces for easy monitoring and management.

3. Smart Factory Systems

MTL 3D supports the transition to smart factories, where interconnected systems and centralized controls drive efficiency.

Key Benefits:

- Real-time production monitoring for better decision-making.

- Optimized resource use to minimize waste.

- Flexible systems that adapt to changing market needs.

Industries Benefiting from MTL 3D

- Aerospace: Ensure compliance and precision with rigorous inspections of critical parts like turbines.

- Defense: Real-time monitoring ensures safety and compliance with military-grade standards.

- Automotive: Achieve defect-free production of components like engines and braking systems while meeting strict safety standards.

- Heavy Machinery: Inspect oversized, complex parts efficiently with robust tools.

Future Trends in Industrial Automation

MTL 3D continues to align its solutions with emerging trends, ensuring its technologies remain relevant as the industry evolves:

- Hyper-Automation: Combining robotics, IoT, and centralized systems for seamless processes.

- Digital Twins: Simulating workflows virtually to optimize production.

- Sustainability: Reducing waste and energy use through efficient systems.

- Human-Machine Collaboration: Enhancing productivity while ensuring safety.

Transform Your Quality Control Today

MTL 3D’s automation solutions empower manufacturers to exceed quality standards, improve operational efficiency, and adapt to evolving market demands.

Key Benefits:

- Consistently deliver flawless products.

- Streamline production without compromising quality.

- Future-proof operations with scalable systems.

Contact MTL 3D today to discover how our solutions can transform your manufacturing processes and help you achieve operational excellence.

#industrialautomation #industrialautomationsolutions #advancedsolutions #advancedengineeringsolutions #mtl3d