Introduction

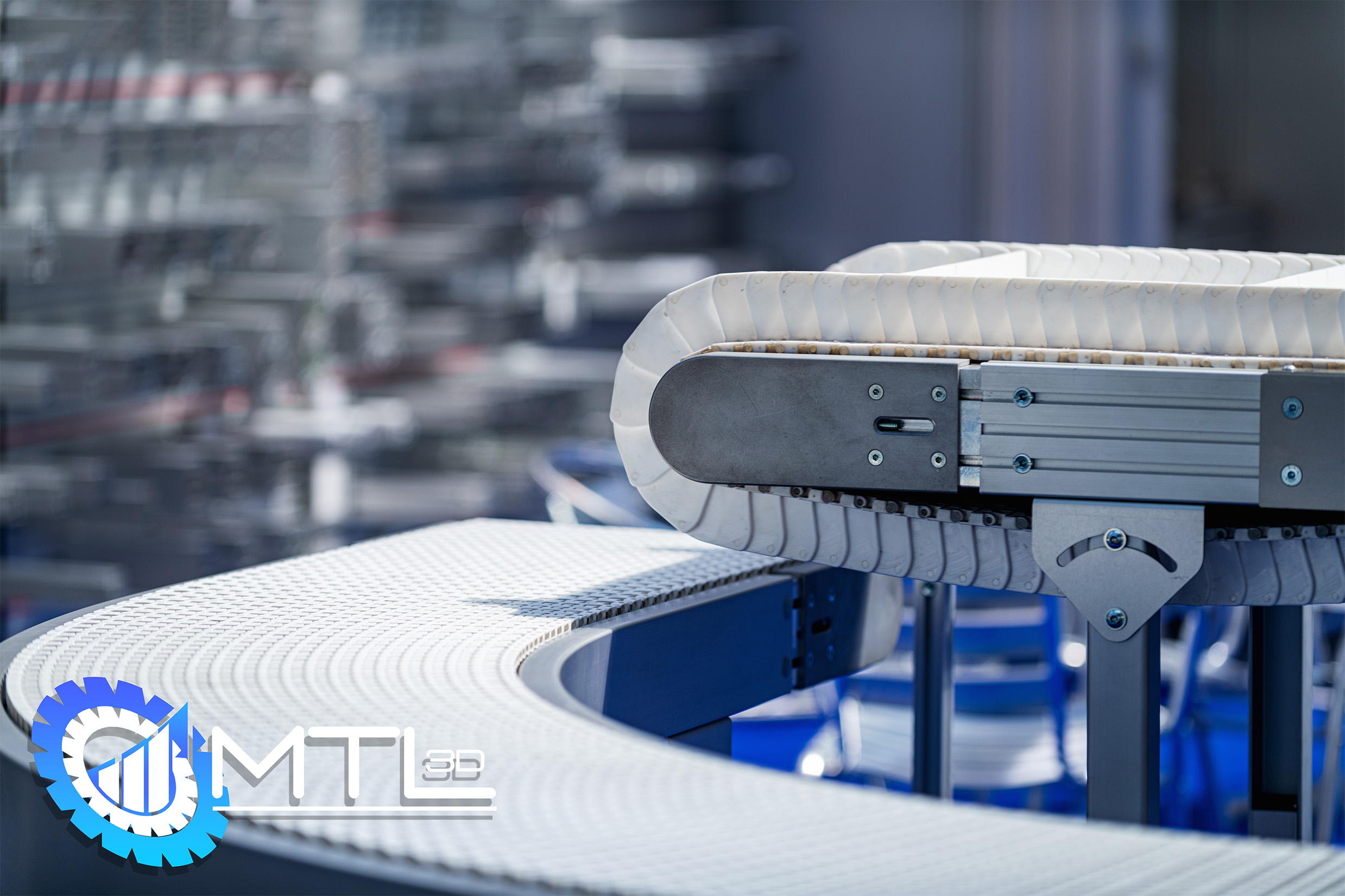

In the dynamic landscape of modern industry, the pursuit of efficiency, precision engineering, and consistency through integrated automation has never been more critical.Studies show that automated quality control systems can reduce inspection time by up to 90% while improving defect detection rates by 50%. As global markets expand and competition intensifies, manufacturers are compelled to adopt innovative solutions that not only meet but exceed stringent quality standards. Integrated automation has emerged as a transformative force in this context, revolutionizing industrial inspection and quality control processes. Companies like MTL 3D are at the forefront of this evolution, offering cutting-edge products and systems that seamlessly blend automation with advanced non-contact inspection technologies.

The Shift from Manual Inspection to Advanced Automated Solutions

Historically, industrial inspection relied heavily on manual methods, where human inspectors visually examined products to identify defects or deviations from specified standards. While human judgment is invaluable, manual inspection is inherently limited by factors such as fatigue, subjectivity, and the inability to detect minute imperfections consistently. As production volumes increased and aerospace manufacturing and product designs became more complex, these limitations posed significant challenges to maintaining quality and efficiency.

The advent of automation marked a pivotal shift in inspection methodologies. Automated inspection systems leverage technologies such as machine vision, artificial intelligence (AI), and robotics to perform inspections with unparalleled speed and accuracy. Machine vision systems, for instance, utilize cameras and image processing algorithms to capture and analyze product images in real-time, detecting defects that are imperceptible to the human eye. AI enhances this capability by learning from vast datasets to identify patterns and predict potential quality issues before they manifest.

MTL 3D exemplifies this transition through its innovative Blazer Systems. These systems are engineered to deliver high-precision measurements and markings, which are essential for industries that demand exacting quality standards. The Blazer Systems are fully automated, minimizing human intervention and thereby reducing the potential for error. Optimized for high-speed operations, they significantly enhance processing speeds and overall productivity. Their versatility allows them to handle a wide range of geometries, making them suitable for diverse applications. Moreover, the integration of advanced software facilitates real-time monitoring, data analysis, and workflow optimization, ensuring that quality control is both rigorous and efficient.

How Integrated Automation Systems Improve Efficiency and Reduce Waste

The integration of automation into inspection systems offers a multitude of benefits that collectively enhance operational efficiency and minimize waste. Key advantages include:

Enhanced Throughput: Automated systems can inspect products at a rate far exceeding that of manual methods. This acceleration reduces bottlenecks in production lines, enabling manufacturers to meet higher demand without compromising quality.

Consistency and Reliability: Automation ensures uniform application of inspection criteria, eliminating variability and ensuring that every product meets predefined quality standards.

Data-Driven Decision Making: Automated inspection systems continuously collect data throughout the production process. This data can be analyzed to identify trends, detect recurring issues, and inform strategic decisions aimed at process improvement.

Waste Reduction: Early detection of defects prevents faulty products from advancing through the production line, thereby conserving materials and reducing the costs associated with rework or scrappage.

MTL 3D’s RoboMate Systems are a testament to the efficiency gains achievable through integrated automation. Equipped with high-accuracy sensors and edge measurement units, RoboMate ensures meticulous quality control with minimal grinding cycles. Its seamless compatibility with Blazer Systems facilitates rapid processing and lowers rejection rates, thereby boosting overall productivity. Advanced algorithms within RoboMate optimize grinding and polishing processes, guided by data from Blazer’s inspections, leading to operations that are both efficient and precise.

Why High-Precision Automation is Essential for Aerospace, Automotive, and Defense Industries

Industries such as aerospace, automotive, and defense operate within frameworks where precision engineering and reliability are paramount. The products and components manufactured for these sectors often perform critical functions where even minor defects can have catastrophic consequences. High-precision automation addresses these stringent requirements by ensuring that every component adheres to exact specifications.

Aerospace: Aircraft components must meet rigorous tolerances to ensure safety and optimal performance. Automated non-contact inspection systems are capable of detecting microscopic defects in complex geometries, ensuring that each part complies with the industry’s stringent standards.

Automotive: The automotive industry is characterized by high production volumes and the need for components that meet exacting quality benchmarks. Automation facilitates the inspection of intricate parts, ensuring functionality and longevity.

Defense: Defense equipment must perform reliably under extreme conditions. Automated quality control ensures that every component is manufactured to precise specifications, maintaining the integrity and effectiveness of defense systems.

MTL 3D has established itself as a leader in providing complex geometry inspection solutions tailored to the needs of these demanding industries. With over 25 years of experience, MTL 3D specializes in non-contact geometry inspection, measurement, and robotic solutions for the aerospace, energy, and manufacturing sectors. Their systems and software are designed to meet the rigorous requirements of industry leaders, ensuring that components are manufactured to the highest standards of precision and quality.

MTL 3D: Pioneering Quality Control and Inspection Solutions

MTL 3D is a leader in integrated automation solutions, specializing in high-precision inspection and quality control systems. With over 25 years of expertise, the company has consistently delivered innovative technologies that optimize industrial processes across aerospace, automotive, defense, and energy sectors.

Cutting-Edge Products

MTL 3D offers a comprehensive range of inspection and automation solutions, including:

Blazer Systems – Advanced laser measurement technology ensuring high precision in non-contact marking and verification, reducing human error and enhancing speed.

RoboMate Systems – Designed for seamless integration with Blazer Systems, providing automated grinding and polishing robotic solutions with minimal waste and maximum efficiency.

Non-Contact Geometry Inspection Solutions – Specialized for complex geometries, ensuring aerospace and automotive components meet stringent industry standards.

Integrated Software Solutions – Offering real-time data analytics, workflow optimization, and AI-driven quality assessments.

How MTL 3D Enhances Industrial Quality Control

Increased Accuracy – High-precision systems eliminate measurement discrepancies, ensuring all parts adhere to strict tolerances.

Process Efficiency – Automated systems streamline operations, minimizing downtime and enhancing throughput.

Data-Driven Insights – AI-powered analytics provide manufacturers with predictive maintenance capabilities and real-time monitoring.

Sustainability & Waste Reduction – Early defect detection prevents material waste and reduces unnecessary production costs.

By integrating cutting-edge automation into industrial inspection, MTL 3D empowers manufacturers to meet the highest quality standards while maintaining efficiency and competitiveness in their respective industries.

Conclusion

The integration of automation into industrial inspection and quality control is revolutionizing manufacturing processes across various sectors. MTL 3D is leading this transformation by providing advanced robotic solutions that enhance precision, efficiency, and adaptability. As industries continue to evolve, the adoption of integrated automation will be pivotal in meeting the increasing demands for quality and reliability. By embracing these cutting-edge technologies, manufacturers can not only improve their operational performance but also gain a competitive edge in an increasingly demanding market.