In modern manufacturing, inspection systems are no longer just about identifying defects—they are about providing actionable insights that drive the entire production process. At MTL 3D, we go beyond inspection, offering a complete turn-key solution that not only analyzes parts but also recommends the next technical and production process stages, ensuring seamless integration with manufacturing workflows.

The Role of Data in Manufacturing Decisions

Inspection generates valuable data, but its true potential lies in using this data to inform and optimize production processes. By integrating inspection systems with automated decision-making capabilities, manufacturers can ensure:

- Efficiency: Faster resolution of quality issues with automated insights.

- Consistency: Repeatable and accurate recommendations reduce variability in production.

- Productivity: Eliminating manual decision-making processes saves time and resources.

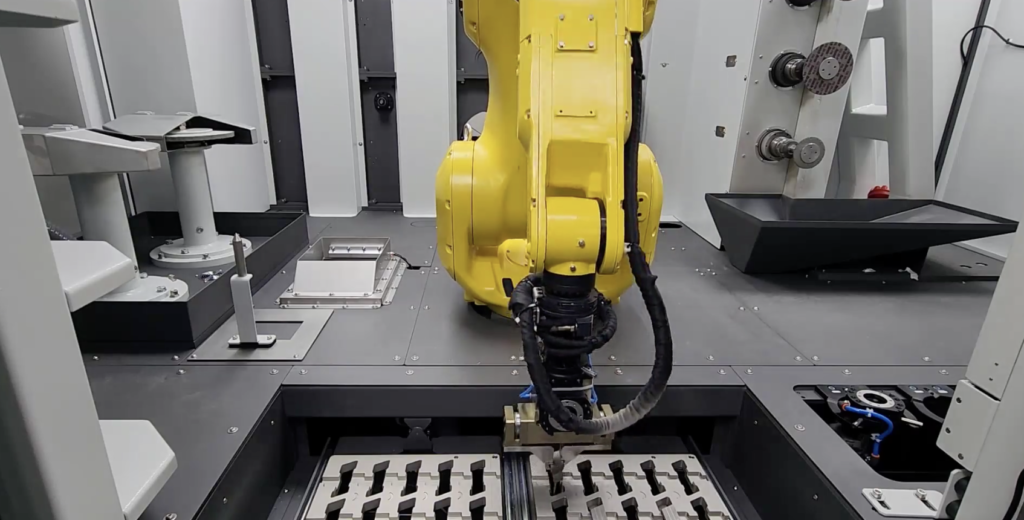

MTL 3D’s Advanced Sorting and Process Recommendations

MTL 3D’s inspection systems, such as Blazer, are equipped with advanced capabilities that do more than detect deviations. They provide automatic sorting recommendations for each inspected part, offering clear guidance on the next process stage.

How It Works:

- Inspection and Analysis: The system scans and inspects the part, comparing it to nominal CAD models.

- Real-Time Sorting Logic: Based on inspection results, the system applies predefined rules to categorize the part.

- Process Recommendations:

- Electro-Chemistry: If specific areas require surface finishing or treatment.

- Forging Die Tuning or Repair: If the part shows deviations indicating tooling issues.

- Local Polishing/Grinding: If corrections are needed in specific areas to meet precision standards.

- Other Production Actions: Tailored to the specific needs of the component and process.

- Comprehensive Reporting: All recommendations are automatically included in a detailed report, ensuring complete traceability and documentation.

The Advantage of Turn-Key Solutions from MTL 3D

MTL 3D’s ability to provide inspection, analysis, and actionable recommendations as a single solution offers several unique advantages:

- Integrated Workflow: Seamlessly connects inspection results with downstream production processes, reducing delays and errors.

- Real-Time Decision Making: Automatic sorting and process recommendations eliminate the need for manual interpretation of data.

- Increased Productivity: Streamlines operations by guiding parts directly to the next production stage without bottlenecks.

- Customizable Rules: Recommendations can be tailored to meet the specific requirements of any production workflow.

Case Study: Streamlining Production with MTL 3D

A major manufacturer of aero engine blades implemented MTL 3D’s inspection system with automated sorting recommendations. Key results included:

- A 30% reduction in production downtime due to streamlined decision-making.

- Enhanced traceability with automated reports detailing process recommendations.

- Improved product quality by ensuring that each part followed the correct next stage, whether polishing, forging die tuning, or other actions.

Why This Matters for Modern Manufacturing

In competitive industries like aerospace and automotive, staying ahead means optimizing every stage of the production process. MTL 3D’s combination of inspection, analysis, and actionable recommendations turns inspection systems into a central hub for quality control and process management.

Conclusion:

With MTL 3D, inspection is just the beginning. By leveraging advanced sorting recommendations and real-time process guidance, our systems empower manufacturers to make smarter, faster decisions, ensuring quality and efficiency at every step. For manufacturers seeking a turn-key solution that bridges inspection and production, MTL 3D delivers unmatched value.

#advancedsolutions #industrialautomationsolutions #mtl3d #inspectionsystems