What’s in This Article

Introduction

In today’s industrial landscape, precision and reliability are essential across sectors such as aerospace, defense, automotive, and energy. Critical components, like aero engine blades, mission-critical defense parts, and automotive systems, require exacting quality standards to ensure performance and safety.

Customized inspection systems provide tailored solutions to meet the diverse needs of these industries, delivering precision, accuracy, and consistency throughout the manufacturing and maintenance lifecycle. At MTL 3D, we specialize in developing customized inspection systems designed for applications ranging from aero engine blades to complex defense and automotive components.

Why Precision Inspection Matters

Industrial components often operate under extreme conditions—high temperatures, intense pressure, and mechanical stress. Any flaw or defect can compromise performance, safety, and reliability. Effective inspection systems must:

- Detect micro-level deviations in geometry, such as distortions, edge irregularities, or surface defects.

- Ensure compliance with strict standards in aerospace, defense, and automotive industries.

- Support longevity and performance by identifying deviations early in production or maintenance cycles.

Failing to address these requirements can lead to safety risks, costly downtime, and reduced operational efficiency—making precision inspection indispensable across industries.

The Role of Customized Inspection Systems

Customized inspection systems are engineered to meet the specific requirements of diverse industries and components. Unlike generic solutions, they address:

- Complex Geometries – Handles intricate shapes such as aero engine blades, automotive engine components, and defense-critical parts.

- High Accuracy Requirements – Delivers micron-level measurements to meet strict tolerances.

- Material Variability – Adapts to diverse materials, including alloys, composites, and specialized coatings.

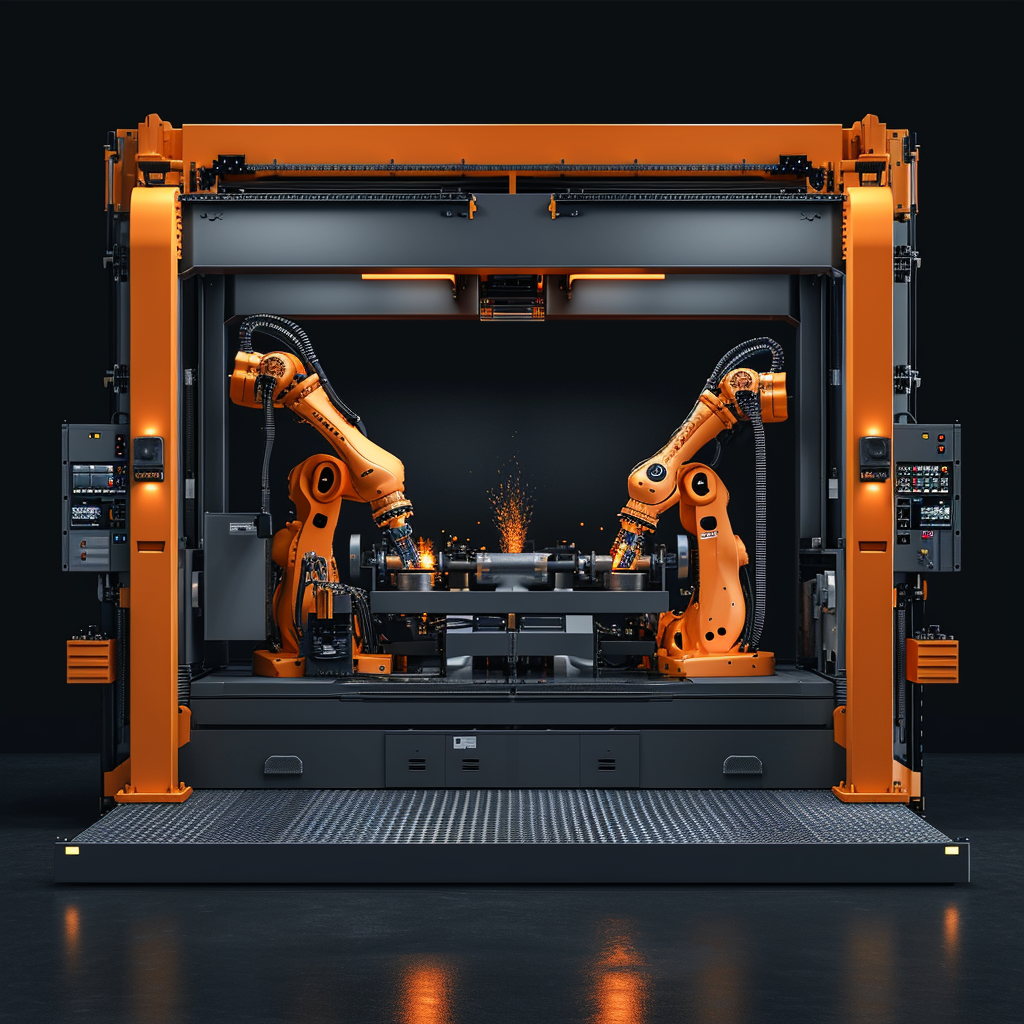

Technologies like non-contact optical measurement, high-speed 3D scanning, and process automation make customized inspection systems a vital tool for ensuring quality and reliability.

How MTL 3D Enhances Quality Control Across Industries

At MTL 3D, we combine decades of expertise with advanced technologies to deliver tailored inspection solutions for multiple sectors. Our systems ensure efficiency, accuracy, and reliability at every stage of the manufacturing process.

Here’s how we make a difference:

- High-Speed Non-Contact Measurement – Delivers fast, accurate inspections without compromising component integrity.

- Customized Solutions – Designed to fit the unique requirements of industries ranging from aerospace to automotive and defense.

- Short Inspection Cycle Times – Optimized workflows reduce production bottlenecks while maintaining precision.

- Comprehensive Data Reporting – Provides actionable insights for subsequent processes such as grinding, polishing, or corrections.

Features of Customized Inspection Systems by MTL 3D

Feature & Benefit

High-Speed 3D Scanning | Quickly captures intricate geometric details for reliable quality checks. |

Non-Contact Measurement | Ensures safe and precise inspections, preserving component integrity. |

Modular Design | Seamlessly integrates with existing manufacturing and quality workflows. |

Repeatability and Accuracy | Delivers consistent, reliable measurements across production cycles. |

Multi-Material Adaptability | Inspects components made from alloys, composites, and coated surfaces. |

Tailored User Interface | Simplifies operations and reporting for diverse industrial applications. |

Applications Across Industries

MTL 3D’s customized inspection systems are relevant to various industries and their unique requirements:

- Aerospace:

- Inspects aero engine blades, IBRs, and clusters with unmatched precision and speed.

- Defense:

- Validates critical components such as missile systems, armored vehicle parts, and radar equipment for compliance with strict standards.

- Automotive:

- Provides high-speed dimensional checks for components such as engine parts, braking systems, and transmission components.

- Energy:

- Examines industrial turbine blades and other energy-critical parts for wear, tear, and geometric accuracy.

- Industrial Applications:

- Supports general manufacturing with solutions for quality control in complex geometries and high-volume production.

The Future of Customized Inspection Technology

As industries evolve, inspection systems must adapt to new challenges. Key trends include:

- Higher-Speed Measurement Systems – Reducing inspection times without compromising accuracy.

- Integrated Process Automation – Combining inspection with feedback systems for automated corrections.

- Enhanced Connectivity – Enabling seamless integration with smart factory systems for optimized workflows.

- Portable Inspection Solutions – Improving flexibility with compact systems for on-site inspections.

At MTL 3D, we continuously innovate to meet the evolving demands of industries, providing clients with cutting-edge solutions that stay ahead of the curve.

Conclusion

Customized inspection systems are essential for ensuring quality and reliability across a wide range of industries. Whether inspecting aero engine blades, mission-critical defense components, or automotive systems, MTL 3D delivers tailored solutions that combine precision, speed, and adaptability.

Contact us today at www.mtl-3d.com to learn how our customized solutions can optimize your quality control processes across industries.