At MTL 3D Ltd., we are redefining the future of inspection and industrial robotic systems through continuous innovation and expertise. Since our founding in 1997, our mission has been clear: pioneer advanced technologies and deliver solutions that meet the highest standards of precision and efficiency.

Our legacy began with a focus on Aero Engine Blade Inspection, where we have developed cutting-edge systems that set the industry benchmark. Over the years, we’ve expanded our capabilities to include:

With over two decades of experience, we remain committed to providing innovative, reliable, and customized solutions that empower manufacturers across industries to achieve excellence.

Since its founding in 1997 as Metroptic, a proud member of the prestigious Iscar IMC group, MTL 3D Ltd. has been a trailblazer in the high-tech industry. Over the years, we have continually expanded our capabilities, developing and advancing innovative solutions that have redefined precision and performance in industrial applications.

In 2019, our rebranding to MTL 3D Ltd. marked a pivotal milestone in our journey. This transformation solidified our identity as an expert in the development and production of automated systems, strengthening our role as a trusted partner in manufacturing innovation.

Our expertise lies in the high-precision inspection of complex geometries, with a particular focus on the intricate geometry of Aero Engine Blades. Our solutions consistently set industry benchmarks for accuracy, reliability, and performance, driving excellence across the aerospace and manufacturing sectors.

Our evolution from Metroptic to MTL 3D Ltd. is not merely a change of name but a reflection of our growth and deepened expertise. Our relentless pursuit of innovation drives us to engineer systems that not only meet but exceed the exacting demands of high-performance inspection. Our suite of offerings has expanded to encompass a diverse range of advanced engineering solutions, each designed with the precision required for the meticulous examination of Aero Engine Blade inspection, a critical component in the aerospace industry.. This dedication to our craft has earned us recognition as a trusted partner for clients seeking the highest standards of quality and reliability.

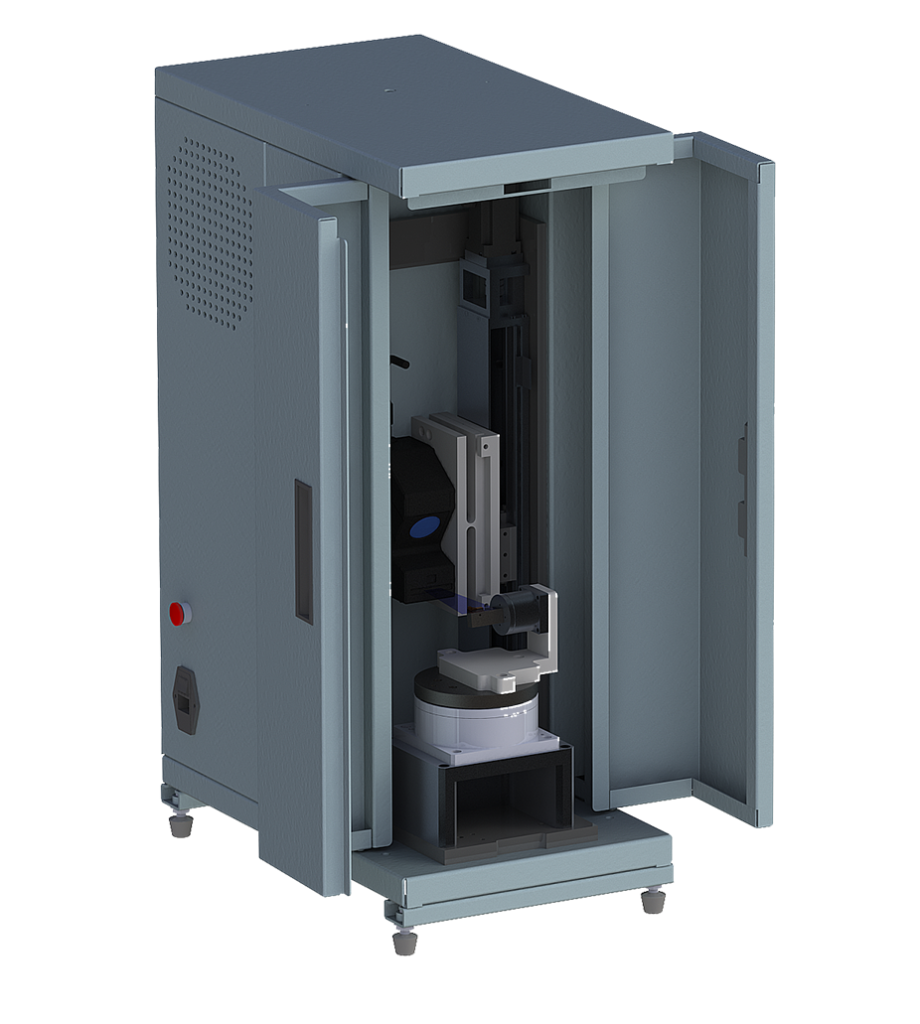

Our BLAZER systems and MARS software stand as pillars of our technological prowess. The BLAZER non-contact 3D inspection system is designed for optimal performance in both in-process and post-process quality control, providing an inspection cycle time that is 4-5 times faster than traditional CMM solutions. This efficiency is a game-changer in industries that rely on precision and speed.

MTL 3D Ltd. caters to a variety of blade types and sizes, with MARS software offering specific programming presets for rotor and vane blades, fan and turbine blades, IBR, and clusters, among others. Our software allows for the selection of appropriate program types for forged and final blades, ensuring that setup parameters are meticulously applied.

Our advanced inspection systems offer a comprehensive examination of root, shroud, and airfoil parameters, allowing for a full range of quality control checks. These systems are capable of selecting various types of alignment and best-fit options, employing different calculation methods, and providing diverse report views to suit client needs.

MTL 3D Ltd. is not just about products; we are about solutions. Our special advanced engineering projects include:

Our commitment to quality is unwavering, with our systems designed for use on the production floor, within automated lines, and in laboratory settings. We ensure that every product leaving the production line meets the highest standards of quality control.