Introduction

Did you know that 62% of aerospace and defense enterprises have adopted smart manufacturing initiatives? It’s not surprising, given the incredible benefits these technologies bring. Smart manufacturing and robotics are no longer futuristic concepts – they’re here, and they’re reshaping industries like never before. From aerospace manufacturing to precision engineering, these innovations are all about boosting efficiency, improving safety, and optimizing workflows.

At MTL 3D, we’re part of this revolution. We design cutting-edge robotic solutions tailored to industries needing the best in automation, non-contact inspection, and workflow optimization. If you’re ready to dive into the world of smart manufacturing, let’s explore how it’s transforming businesses across the globe.

What is Smart Manufacturing?

Smart manufacturing is the integration of advanced technologies like robotics, artificial intelligence (AI), and the Internet of Things (IoT) into production systems. Think of it as an interconnected ecosystem where machines, devices, and humans work together seamlessly. It’s not just about making things faster – it’s about making them smarter.

For example, smart factories use IoT sensors to monitor equipment in real time. These sensors gather data on performance, temperature, and output, which AI then analyzes to improve efficiency. This results in fewer delays, better quality control, and reduced costs.

At MTL 3D, our systems, such as Blazer and RoboMate, embody this philosophy. These products don’t just perform tasks; they analyze, adapt, and optimize every step of the process, ensuring precision engineering at every turn. Whether it’s non-contact inspection or advanced robotic grinding and polishing, smart manufacturing is the way forward.

The Evolution of Robotics in Manufacturing

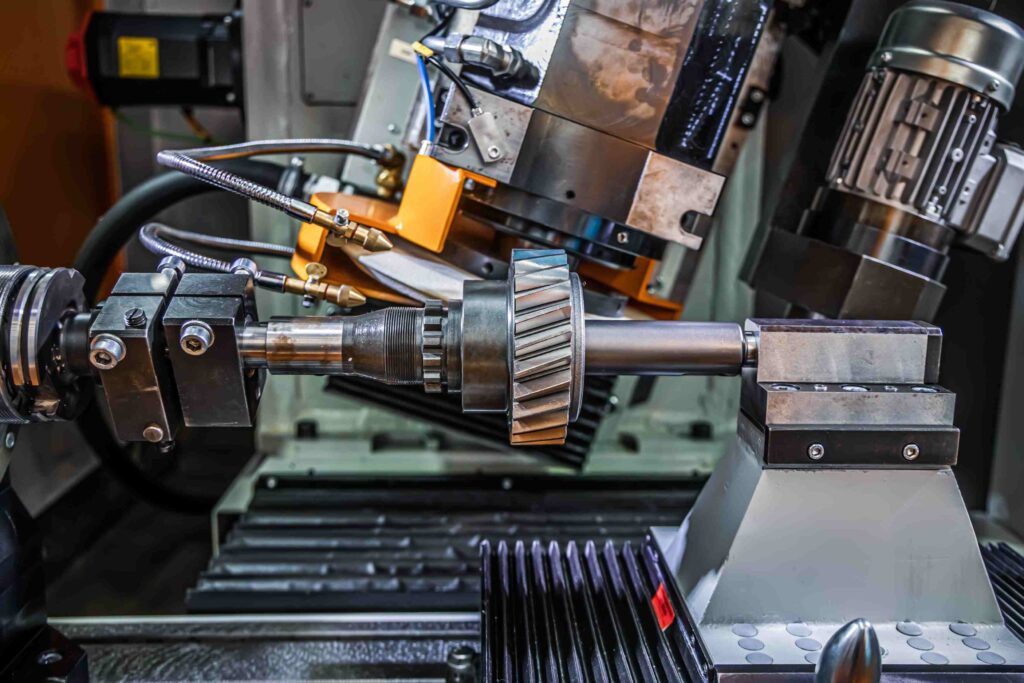

Manufacturing has come a long way. Decades ago, robots were introduced to handle repetitive tasks like assembly and welding. But today? Robots have evolved into intelligent, adaptable systems capable of working alongside humans.

Early industrial robots were programmed for fixed tasks, often working in isolation due to safety concerns. However, the development of collaborative robots (cobots) has changed the game. Cobots are equipped with advanced sensors, enabling them to detect human presence and adjust their actions accordingly.

The rise of cobots has been particularly impactful in industries like aerospace manufacturing, where precision engineering is essential. For example, MTL 3D’s RoboMate system is designed to polish aero-engine blades with incredible accuracy. It not only improves efficiency but also ensures a safer and more adaptable work environment.

Key Benefits of Smart Manufacturing and Robotics

Enhanced Productivity

Productivity is the backbone of any manufacturing operation. Robots and automation systems can work around the clock, delivering consistent results without fatigue. This is especially valuable in high-demand industries like aerospace manufacturing.

At MTL 3D, our Blazer system exemplifies this benefit. By combining advanced optical measuring technology with automated workflows, Blazer ensures maximum output with minimal waste. It’s the ultimate tool for precision engineering.

Cost Reduction

Let’s face it – manufacturing costs can add up quickly. From raw materials to labor and maintenance, every aspect of production requires careful budgeting. Smart manufacturing helps reduce these costs in several ways:

- Fewer Errors: Automation minimizes human errors, saving time and materials.

- Predictive Maintenance: AI systems identify potential issues before they escalate, reducing downtime.

- Efficient Resource Use: IoT devices monitor energy and material consumption, ensuring nothing goes to waste.

MTL 3D’s solutions, like the fully automated Blazer system, are designed with cost efficiency in mind. By streamlining processes and optimizing resources, we help businesses achieve significant savings.

Improved Safety

Safety is a top priority in manufacturing environments, and robotics plays a crucial role in protecting workers. Dangerous tasks, such as welding, cutting, and working with hazardous materials, can now be handled by robots.

At MTL 3D, we prioritize safety without compromising efficiency. Our robotic solutions are built to handle high-risk tasks, ensuring that human workers remain out of harm’s way. This creates a safer, more productive workspace for everyone involved.

Increased Flexibility

Flexibility is essential in today’s fast-paced manufacturing world. With market demands constantly changing, businesses need systems that can adapt quickly. Smart robots are highly versatile, capable of switching between tasks with minimal downtime.

For example, MTL 3D’s RoboMate system can be reconfigured to handle a variety of polishing and grinding tasks. This adaptability ensures that manufacturers stay competitive, no matter how dynamic the industry becomes.

Sustainability

Sustainability is more than a buzzword – it’s a necessity. Smart manufacturing supports eco-friendly practices by reducing waste, optimizing resource use, and minimizing energy consumption.

At MTL 3D, we’re committed to helping businesses achieve their sustainability goals. Our robotic solutions enable manufacturers to reduce their environmental footprint while maintaining high productivity levels.

How Smart Technologies Address Industry Challenges

The manufacturing world is no stranger to challenges. Labor shortages, supply chain disruptions, and rising consumer expectations have pushed companies to innovate. Enter smart technologies.

Take the COVID-19 pandemic as an example. Supply chain disruptions forced many companies to reevaluate their operations. Those with automated systems in place were able to adapt quickly, maintaining production even under challenging circumstances.

At MTL 3D, we’ve seen firsthand how smart manufacturing can address these challenges. Our solutions are designed to optimize workflows, enhance supply chain visibility, and keep production lines running smoothly, no matter what.

The Role of AI and IoT in Smart Factories

Artificial intelligence and the Internet of Things are the brains behind smart manufacturing. Together, they enable real-time data collection, analysis, and decision-making.

For instance, IoT sensors can monitor equipment performance and send alerts when maintenance is needed. AI systems then analyze this data, predicting issues before they cause downtime. This combination of technologies creates a more efficient and reliable production process.

At MTL 3D, our products integrate AI and IoT to deliver unparalleled results. Whether it’s non-contact inspection or automated grinding, our systems ensure precision, efficiency, and reliability.

Collaborative Robotics (Cobots)

Cobots are the friendly robots of the manufacturing world. Unlike traditional robots that need to be fenced off, cobots work hand-in-hand with human operators. They’re designed to be safe, intuitive, and highly adaptable.

Take MTL 3D’s RoboMate, for example. It’s a cobot that specializes in precision tasks like polishing aero-engine blades. It works alongside humans, handling repetitive tasks while operators focus on quality control and innovation. RoboMate enhances workflow optimization while maintaining a safe and collaborative work environment.

Future Trends in Smart Manufacturing

The future of smart manufacturing is bright, with several exciting trends on the horizon:

- AI-Powered Insights: Machines will get even better at predicting issues before they arise.

- IoT Expansion: Smarter devices mean more connected factories and streamlined operations.

- Sustainability Goals: Eco-friendly practices will become the norm, supported by advanced technologies.

MTL 3D is already preparing for these trends. By staying ahead of the curve, we ensure our customers have access to the best tools and technologies available.

Conclusion

Smart manufacturing and robotics are no longer just buzzwords – they’re the backbone of modern industry. From aerospace manufacturing to precision engineering, these technologies are driving efficiency, improving safety, and optimizing workflows. Companies like MTL 3D are leading the way with innovative solutions that adapt to industry demands while pushing the boundaries of what’s possible.

Whether you’re exploring non-contact inspection or looking to enhance productivity with robotic solutions, one thing is clear: the future of manufacturing is smart, and it’s already here. Visit MTL-3D LTD and speak to a team member to see how we can help you in your smart manufacturing process.

#smartmanufacturing #mtl3d