Introduction

Did you know that supply chain manufacturing and industrial robotics is projected to reach $21 billion by 2029? That’s a massive surge driven by increasing demand for automation, precision engineering, and workflow optimization. From aerospace manufacturing to high-speed warehouse logistics, robots are revolutionizing how businesses operate, making supply chains and manufacturing processes faster, safer, and more efficient.

At MTL 3D, we’re at the forefront of this robotic transformation. Our cutting-edge robotic solutions, from non-contact inspection to robotic grinding and polishing, help manufacturers and logistics companies maximize efficiency and maintain the highest level of precision. Whether you’re looking to optimize production speed, reduce defects, or enhance safety, robotics is the key to future-proofing your business.

What Are Industrial and Autonomous Robots?

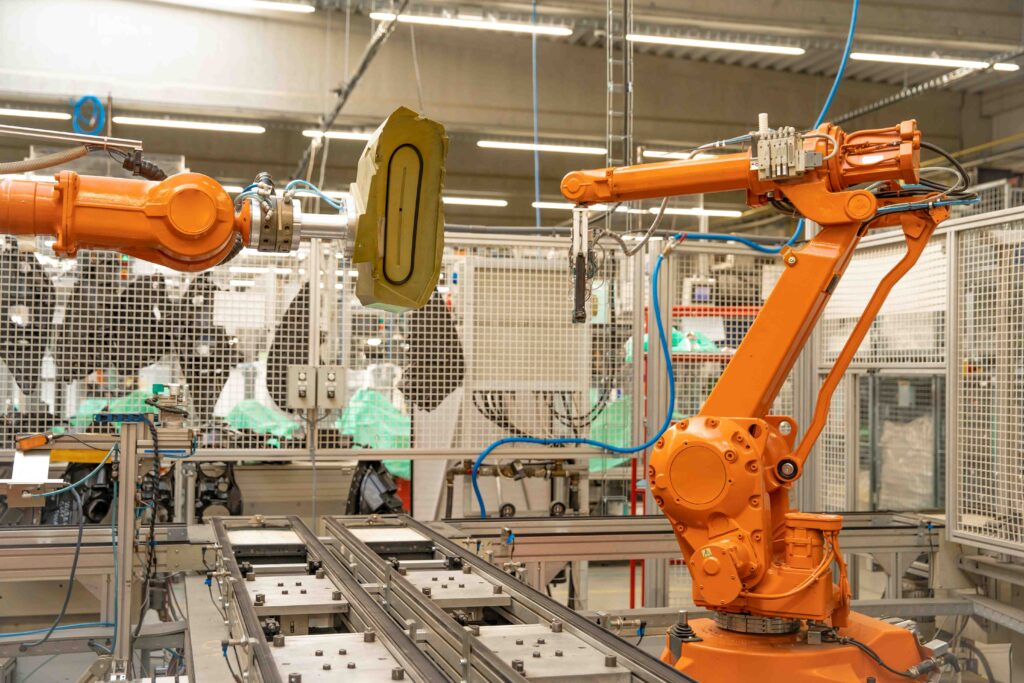

Robots in manufacturing and supply chains come in many forms, but they all serve a singular purpose—automating processes with unparalleled precision and efficiency.

Industrial Robots

Industrial robots are programmable automated systems designed to perform repetitive tasks with speed and accuracy. These machines feature:

✔ Automated motion control for high-speed part handling

✔ Sensor-based measurement for real-time quality checks

✔ Advanced programming for process automation

At MTL 3D, we integrate robotic automation into machining, inspection, laser welding, and finishing processes to reduce cycle times and enhance quality assurance.

Autonomous Robots in Supply Chains

Autonomous robots, such as Autonomous Mobile Robots (AMRs), operate with minimal human intervention. They navigate warehouses, transport goods, and optimize logistics, significantly reducing errors and improving efficiency.

Key Benefits of Robotics in Supply Chain and Manufacturing

Improving Efficiency and Accuracy

Robots bring unmatched precision to manufacturing and logistics. Whether it’s AI-powered inventory managementor robotic CNC-integrated measurement, companies experience:

✔ Elimination of human error in quality control

✔ Reduction of defects and material waste

✔ Optimized speed and accuracy in machining and warehouse operations

For example, MTL 3D’s Blazer Systems automate non-contact inspection, helping manufacturers reduce defects and maintain tight tolerances.

Reducing Production Costs

Automation not only boosts efficiency but also cuts costs. With robotic grinding, polishing, and laser welding, businesses can: ✔ Minimize material waste with precise control

✔ Lower labor expenses by automating repetitive tasks

✔ Reduce downtime with AI-driven maintenance

At MTL 3D, our RoboMate Systems optimize material finishing, allowing manufacturers to scale production without inflating costs.

Enhancing Workplace Safety

By replacing hazardous manual labor with robotic solutions, businesses can:

✔ Reduce worker exposure to high-speed machining, heat, and hazardous materials

✔ Automate heavy lifting to prevent workplace injuries

✔ Ensure compliance with strict safety standards

From robotic laser welding to fully automated inspection, MTL 3D’s solutions prioritize worker safety while maintaining productivity.

Core Applications of Robotics in Industrial Supply Chains

Robotic Inspection & CNC-Integrated Measurement

MTL 3D’s Blazer Systems integrate real-time robotic inspection, eliminating the need for manual quality control:

✔ High-speed scanning for non-contact inspection

✔ Automated tolerance verification directly on CNC machines

✔ Minimized post-production corrections

Robotic Grinding and Polishing

RoboMate Systems offer:

✔ Consistent material removal, reducing surface defects

✔ Dynamic adaptation to different finishing requirements

✔ Faster processing compared to manual polishing

Robotic Laser Welding with Seam Tracking & Weldment Monitoring

MTL 3D’s robotic laser welding solutions ensure:

✔ Seam tracking technology for perfect weld alignment

✔ Weldment monitoring for real-time quality assurance

✔ Stronger, defect-free welds

The Role of Engineers in an Automated Manufacturing Environment

While robots handle repetitive tasks, engineers now focus on:

✔ Programming automation workflows

✔ Analyzing manufacturing data

✔ Fine-tuning robotic grinding, polishing, and welding systems

At MTL 3D, we support robotic training and integration to help manufacturers maximize automation potential.

Challenges in Implementing Robotics

Businesses often face hurdles when implementing robotics, such as:

🔸 High Initial Costs – MTL 3D provides modular robotic solutions for scalable investment.

🔸 Integration Complexity – Our systems seamlessly integrate with existing CNC machining, finishing, and inspection processes.

🔸 Skill Gaps – We offer training programs to ensure smooth adaptation to robotic systems.

Future of Robotics in Supply Chain and Industrial Manufacturing

The future of robotic solutions includes:

✔ AI-driven robotic inspection integrated with CNC machines

✔ Fully automated robotic grinding and polishing

✔ Precision laser welding with real-time monitoring

✔ Expanded use of autonomous mobile robots in warehouses

At MTL 3D, we continue to innovate, ensuring manufacturers and logistics companies stay ahead of the competition.

Conclusion: MTL 3D’s Role in Driving Automation and Precision

Robotic automation isn’t just the future—it’s happening now. Companies adopting robotic solutions experience:

✔ Higher efficiency and accuracy

✔ Lower costs and reduced waste

✔ Enhanced workplace safety

🚀 Get in touch with MTL 3D today and start optimizing your workflow!

📍 Visit www.mtl-3d.com for more details.