Table of Contents:

- Introduction

- Understanding Engineering Solutions in the Defense Sector

- What Are Engineering Solutions in Defense?

- The Role of Engineering in Defense Projects

- Core Components of Engineering Solutions in Defense

- Problem-Solving Approaches

- Integration of Advanced Technologies

- Collaboration with Defense Contractors

- Focus on Efficiency and Sustainability

- The Potential Impact of Engineering Solutions in Defense

- Engineering Solutions in Action: Case Studies

- Addressing Challenges in Defense Engineering

- The Future of Engineering Solutions in Defense

- Conclusion

Introduction

Global military spending reached $2.24 trillion in 2022, according to the Stockholm International Peace Research Institute (SIPRI). This significant investment reflects the increasing demand for advanced defense technologies to ensure national security and operational superiority. Central to these advancements are engineering solutions—innovative tools and techniques that address complex manufacturing challenges.

MTL 3D is focused on becoming a key player in this evolving landscape by developing precision engineering and inspection systems designed to enhance durability, streamline production, and ensure the highest quality in critical components. While MTL 3D has not yet supplied systems to the defense sector, the company is actively positioning itself to offer solutions that meet the stringent requirements of military applications.

Understanding Engineering Solutions in the Defense Sector

The defense sector relies heavily on advanced engineering solutions to maintain the performance and resilience of essential components. From missile casings to armored vehicle parts, defense systems must withstand extreme conditions without compromising quality or safety.

MTL 3D is preparing to deliver precision engineering systems capable of meeting the rigorous demands of defense manufacturing.

What Are Engineering Solutions in Defense?

Defining Engineering Solutions

In defense, engineering solutions apply technical expertise, specialized tools, and innovative designs to address manufacturing challenges. These solutions ensure that components are produced with high precision, adhering to strict tolerances and quality standards.

Examples include:

- MTL 3D’s Blazer Systems – Advanced non-contact measurement systems that verify component geometry with high accuracy, reducing errors and rework.

- RoboMate – A robotic grinding and polishing system that ensures components achieve the required finish and dimensional precision.

Although these technologies are currently used in sectors such as aerospace and automotive, they hold significant potential for defense applications.

The Role of Engineering in Defense Projects

The defense industry relies on engineers to design, inspect, and enhance military technologies. From aircraft components to ground vehicle systems, each part must meet stringent specifications to ensure reliable performance in demanding environments.

MTL 3D is developing solutions that could support this process, including:

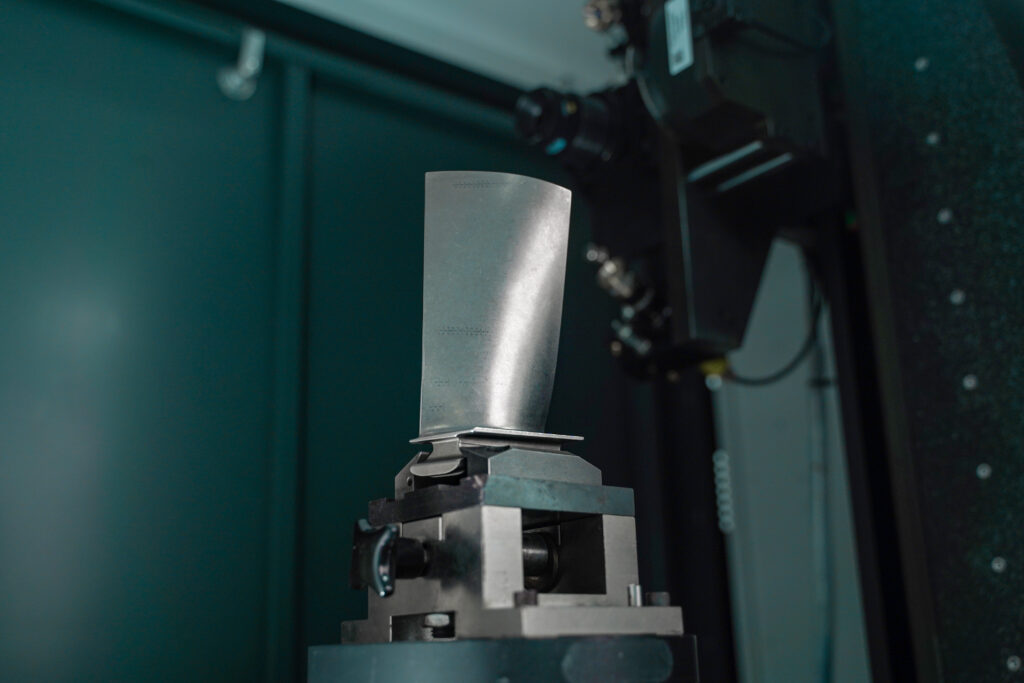

- Blazer Systems – For geometry inspections of aero engine blades and high-precision components.

- RoboMate – Automating grinding and polishing to reduce manufacturing times and increase accuracy.

Although these systems are not yet deployed in defense, MTL 3D is ready to adapt them for future military applications.

Core Components of Engineering Solutions in Defense

1. Problem-Solving Approaches

Defense manufacturing faces unique challenges—such as producing stealth technologies, high-durability components, and complex geometries. MTL 3D is developing solutionsdesigned to address these challenges through automation and precision engineering.

Example:

- Blazer Systems – Ideal for inspecting intricate surfaces that traditional methods struggle to assess.

2. Integration of Advanced Technologies

Modern defense manufacturing incorporates automation, robotics, and intelligent software. MTL 3D’s solutions focus on:

- Real-time data monitoring using MARS Software.

- Automated grinding and polishing with RoboMate to reduce manual labor and ensure consistency.

3. Collaboration Among Stakeholders

MTL 3D works closely with defense contractors to understand specific project needs and develop tailored solutions. This approach ensures that MTL 3D’s systems can seamlessly integrate into existing workflows when the opportunity arises.

4. Focus on Efficiency and Sustainability

Defense manufacturers are increasingly adopting sustainable practices. MTL 3D’s systems are designed to minimize material waste and energy consumption by optimizing production processes.

- RoboMate reduces cycle times and improves material utilization during grinding and polishing.

The Potential Impact of Engineering Solutions on Modern Defense

Enhancing Battlefield Safety and Performance

Precise engineering contributes to the production of durable and reliable military equipment. MTL 3D’s systems could help manufacturers detect flaws early, reducing the risk of operational failures.

Improving Tactical Advantage

High-precision manufacturing allows military forces to benefit from advanced weapons, aircraft, and vehicles. MTL 3D’s technology, once tailored for defense, could play a role in supporting the development of mission-critical systems.

Engineering Solutions in Action: Case Studies

Blazer Systems – Precision in Manufacturing

Currently, MTL 3D’s Blazer Systems are applied in the aerospace sector to inspect and measure complex components. These systems can be adapted to defense applications to ensure components meet strict specifications and quality standards.

RoboMate – Automated Grinding and Polishing

RoboMate enhances manufacturing by automating grinding and polishing processes for precision components. This system holds potential for future defense projects requiring high-accuracy finishing.

Addressing Challenges in Defense Engineering

Managing Innovation and Costs

Defense innovation can be expensive. MTL 3D focuses on scalable solutions that can be applied across sectors, spreading development costs while maintaining high production standards.

Keeping Pace with Technological Advancements

MTL 3D regularly updates its inspection and grinding systems to stay aligned with evolving technologies, ensuring readiness for defense applications.

The Future of Engineering Solutions in Defense

Supporting Autonomous Systems

As autonomous systems gain traction in defense, MTL 3D is developing technologies to ensure that critical components are inspected and finished to the highest standards.

Strengthening Defense Infrastructure

MTL 3D’s solutions are designed to produce resilient, high-quality components that support defense infrastructure and contribute to national security.

Conclusion

Why Engineering Solutions Matter in Defense

While MTL 3D has not yet supplied systems to the defense sector, the company is actively positioning itself to provide high-precision engineering and inspection solutions tailored for military applications.

Looking Ahead: MTL 3D’s Role in Defense Innovation

MTL 3D is committed to developing the tools and technologies necessary to support defense manufacturing, ensuring precision, efficiency, and reliability in future military projects.

Learn more about MTL 3D’s evolving solutions by visiting www.mtl-3d.com.