Introduction

In today’s industrial landscape, precision and accuracy are critical for ensuring product quality, meeting regulatory standards, and optimizing efficiency. Manufacturers in sectors like aerospace, automotive, and energy depend on exact measurements to drive operational success.

Precision metrology services provide the tools and expertise needed to achieve these goals. MTL 3D delivers advanced engineering solutions that help manufacturers streamline processes, enhance quality, and reduce operational risks—positioning them for long-term success in competitive markets.

What Is Metrology?

Metrology is the science of measurement, underpinning various aspects of technology, science, and industry.

When we think about metrology, geometry analysis often comes first—measuring dimensions, angles, and surfaces to ensure parts fit and function precisely.

In manufacturing, even single microns matter. Metrology ensures that components like turbine blades, engine parts, and electronics meet exact specifications, preventing defects and ensuring reliability.

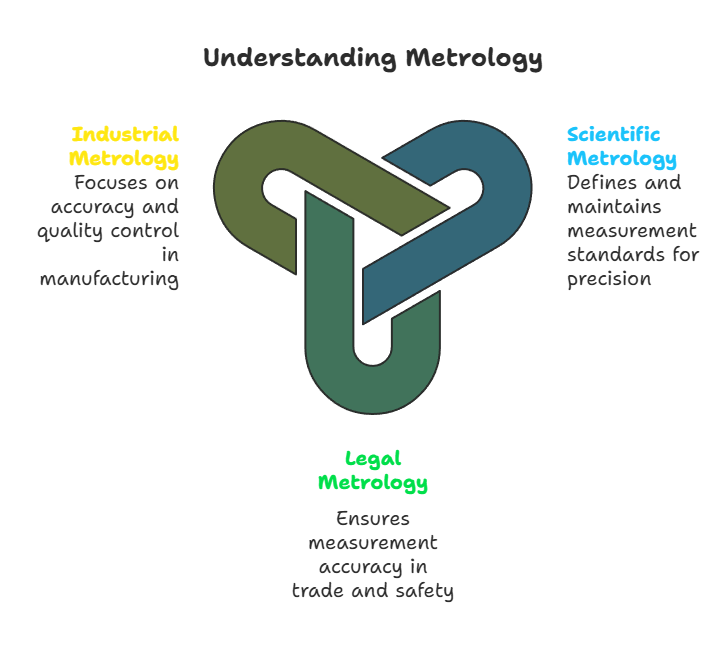

The Three Types of Metrology

Metrology is divided into three primary categories:

Scientific Metrology

Lays the foundation for all measurements by defining and maintaining standards.

- Consider satellite calibration or aerospace measurements, where extreme precision is required to maintain operational accuracy.

Legal Metrology

Ensures accuracy in measurements that affect trade, safety, and compliance.

- From fuel dispensers to medical devices, legal metrology safeguards public trust by guaranteeing fair and accurate measurements.

Industrial Metrology

Industrial metrology is concerned with the application of measurement science in manufacturing and production.

Focuses on production accuracy and quality control.

- Involves calibration, dimensional verification, and surface analysis to ensure manufacturing processes meet tight tolerances and industry standards.

The Importance of Industrial Metrology

Industrial metrology plays a vital role in maintaining product quality, operational efficiency, and regulatory compliance. Key benefits include:

- Enhanced Product Quality: Accurate measurements reduce errors, ensuring products meet design specifications.

- Operational Efficiency: Early detection of deviations minimizes rework and material waste.

- Regulatory Compliance: Adherence to metrology standards ensures manufacturers meet international quality benchmarks.

- Cost Savings: Precision reduces scrap, rework, and overall production costs, boosting profitability.

Precision Metrology Services: Ensuring Quality and Accuracy

Precision metrology services ensure consistent and accurate measurements throughout manufacturing processes. These services typically include:

- Instrument Calibration: Maintaining tool accuracy over time.

- Dimensional Inspection: Verifying part dimensions meet design requirements.

- Surface Analysis: Detecting surface flaws that could impact product performance.

By investing in precision metrology, manufacturers reduce downtime, minimize errors, and enhance product consistency.

Advanced Engineering Solutions in Metrology

Technological advancements have significantly enhanced metrology practices. Modern metrology is driven by automation, robotics, and intelligent software.

Key advancements include:

- Automated Measurement Systems: Accelerate inspections with minimal human intervention.

- Robotic Integration: Automates grinding, polishing, and measurement tasks with high repeatability.

- Real-Time Data Analysis: Enables instant feedback and corrective actions, ensuring continuous quality improvement.

These innovations boost accuracy, productivity, and operational agility, empowering manufacturers to meet the demands of today’s industrial landscape.

MTL 3D's Products and Their Role in Metrology

MTL 3D offers cutting-edge products that cater to the evolving needs of industrial metrology. Let’s explore their core offerings:

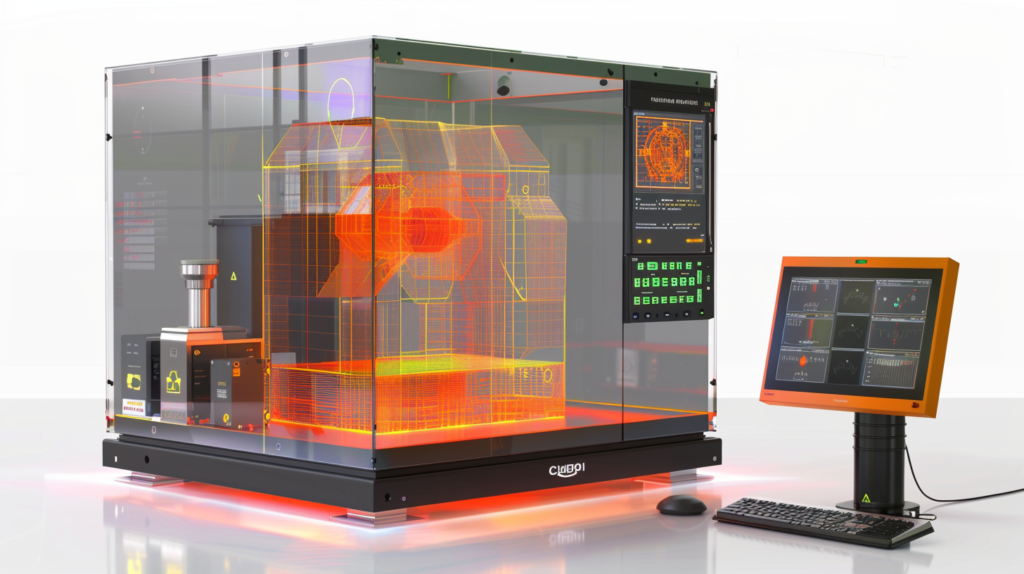

Blazer Systems

Blazer Systems are high-speed optical inspection tools designed for complex geometries. Features include:

- Automation reduces manual oversight.

- Micron-Level Accuracy ensures consistent measurements.

- Versatility supports diverse components across industries.

Blazer Systems are ideal for industries requiring meticulous inspection processes.

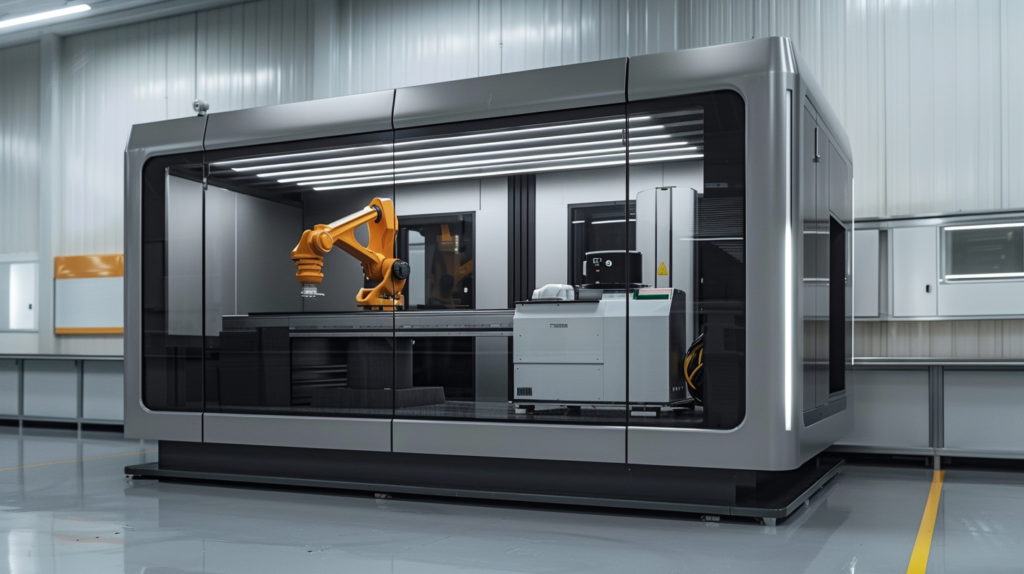

RoboMate Systems

The RoboMate system is an adaptive robotic solution for automated grinding and inspection. Its features include:

- Integrated Sensors ensure precise dimensional control.

- Optimized Grinding Cycles minimize waste and reduce production time.

- Seamless Integration with Blazer Systems allows for end-to-end metrology and finishing.

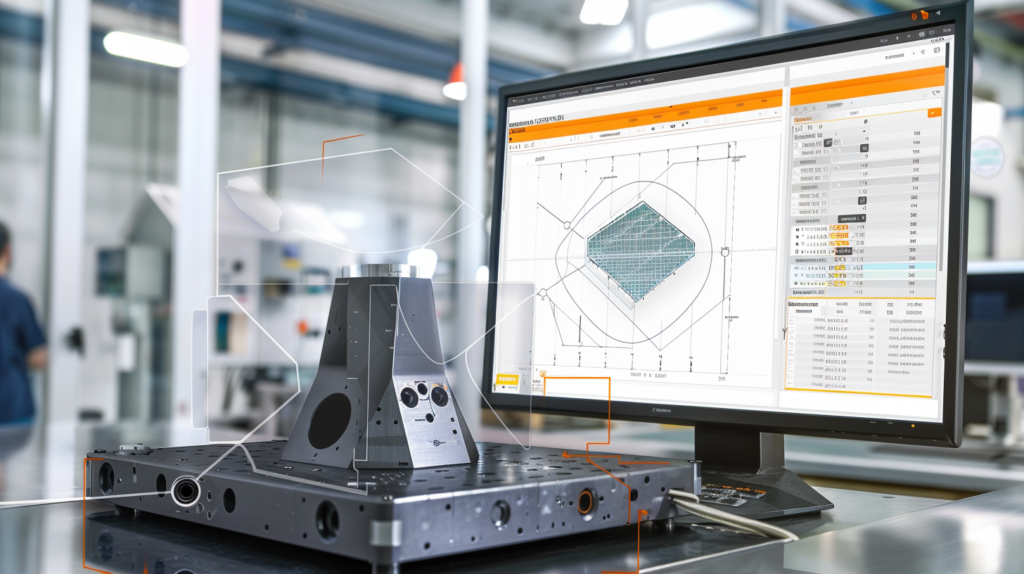

MTL 3D Software

MTL 3D’s proprietary software enhances metrology through:

- Custom Reports for traceability and compliance.

- User-Friendly Interfaces simplifying complex tasks.

- Visual Analysis Tools to highlight irregularities and inconsistencies.

This software complements hardware solutions to provide a comprehensive metrology toolkit.

Interested in a demo of our MTL 3D Software? Contact us.

Real-World Impact: Blazer in Aerospace Manufacturing

A leading aerospace manufacturer applied MTL 3D’s Blazer System not only for geometry inspections but also to measure the depth of serial number stamping on aero engine blades—critical for technical compliance.

Challenge:

Traditional methods required multiple setups and different machines, increasing the risk of human error and slowing production.

Solution:

By leveraging the Blazer System, the manufacturer could inspect part geometry and stamping depth in one automated process.

Results:

- Faster Inspections: Eliminated the need for part remounting.

- Reduced Errors: Minimized human oversight and operational stages.

- Cost Savings: Improved production flow and reduced operational bottlenecks.

How MTL 3D Enhances Industrial Metrology

MTL 3D’s products and services address key challenges in industrial metrology:

Automation: Automated systems reduce human error and increase throughput.

Precision: High-accuracy sensors ensure that measurements meet stringent industry standards.

Integration: Solutions integrate seamlessly into existing workflows for process efficiency.

Flexibility: Products adapt to various geometries and applications, providing versatile solutions.

By adopting MTL 3D’s advanced solutions, manufacturers can achieve unparalleled precision, efficiency, and reliability in their metrology processes.

The Future of Metrology: Innovation and Integration

As manufacturing embraces Industry 4.0 and smart factories, metrology is evolving to meet new demands:

- Self-Learning Systems: Automated tools that self-calibrate and adjust to maintain accuracy.

- Connected Ecosystems: Metrology tools that integrate with entire production lines, streamlining data and process flows.

- Adaptive Measurement Technologies: Systems capable of adjusting to changing materials and designs without reprogramming.

MTL 3D is developing solutions that align with these trends, helping clients stay competitive as technology advances.

Conclusion

Precision metrology services are essential for maintaining the quality and reliability of industrial processes. With its advanced engineering solutions and innovative products, MTL 3D empowers manufacturers to meet the demands of modern industry. From the high-speed capabilities of Blazer Systems to the adaptive functionalities of RoboMate, MTL 3D’s offerings represent the future of industrial metrology. By integrating these solutions, businesses can ensure accuracy, optimize operations, and maintain a competitive edge in the marketplace.