What’s in This Article

- Introduction to IBR and Clusters

- Why Inspection of IBRs and Clusters Matters

- Current Methods vs. MTL 3D’s Blazer Solution

- Key Features of MTL 3D’s Inspection Systems

- Applications of IBR and Cluster Inspection

- How MTL 3D Enhances Efficiency

- Integration with MTL 3D’s Ecosystem

- Technical Parameters of MTL 3D’s IBR and Cluster Solutions

- Final Thoughts

Introduction to IBR Inspection and Clusters

In modern aerospace manufacturing, Integrally Bladed Rotors (IBRs) and blade clusters are critical for engine performance, safety, and operational efficiency. These components are engineered as a single solid unit, ensuring structural integrity and optimal airflow under extreme conditions. Unlike traditional designs using individual blades mounted onto rings—requiring complex compensations for geometric deviations—IBRs eliminate such challenges by maintaining consistent tolerances across the entire part.

MTL 3D’s solutions are versatile, offering full geometry inspection systems for single blades and integrated inspection for IBRs on the same platform. This flexibility ensures that manufacturers can address the unique demands of both configurations while optimizing their production workflows.

Why IBR Inspection and Clusters Matters

IBR inspection and blade clusters operate in extreme conditions, facing high temperatures, intense pressure, and rotational forces. Flaws in these components can severely impact:

- Safety: Ensuring structural integrity to prevent catastrophic failures.

- Fuel Efficiency: Minimizing aerodynamic inefficiencies caused by geometric deviations.

- Vibration Control: Reducing wear and tear from imbalanced rotors.

Effective inspection ensures compliance with strict aerospace standards while enhancing reliability and performance.

Current Methods vs. MTL 3D’s Blazer Solution

Current Conventional Methods

Many manufacturers rely on fragmented workflows for IBR inspection, including:

- Airfoil Inspection: Conducted using mechanical probe systems prone to inaccuracies.

- Ring Features Inspection: Features such as holes, slots, fillets, and breaking edges are partially inspected using manual replicas—flexible materials hardened and measured via comparators.

- Visual Inspection: Some critical areas are checked manually, relying heavily on operator expertise.

Challenges of Conventional Methods:

- Inspection spans multiple stations, taking 8–10 hours per part.

- Requires 3–4 operators, increasing labor costs and leaving room for inconsistency.

MTL 3D’s Blazer Solution

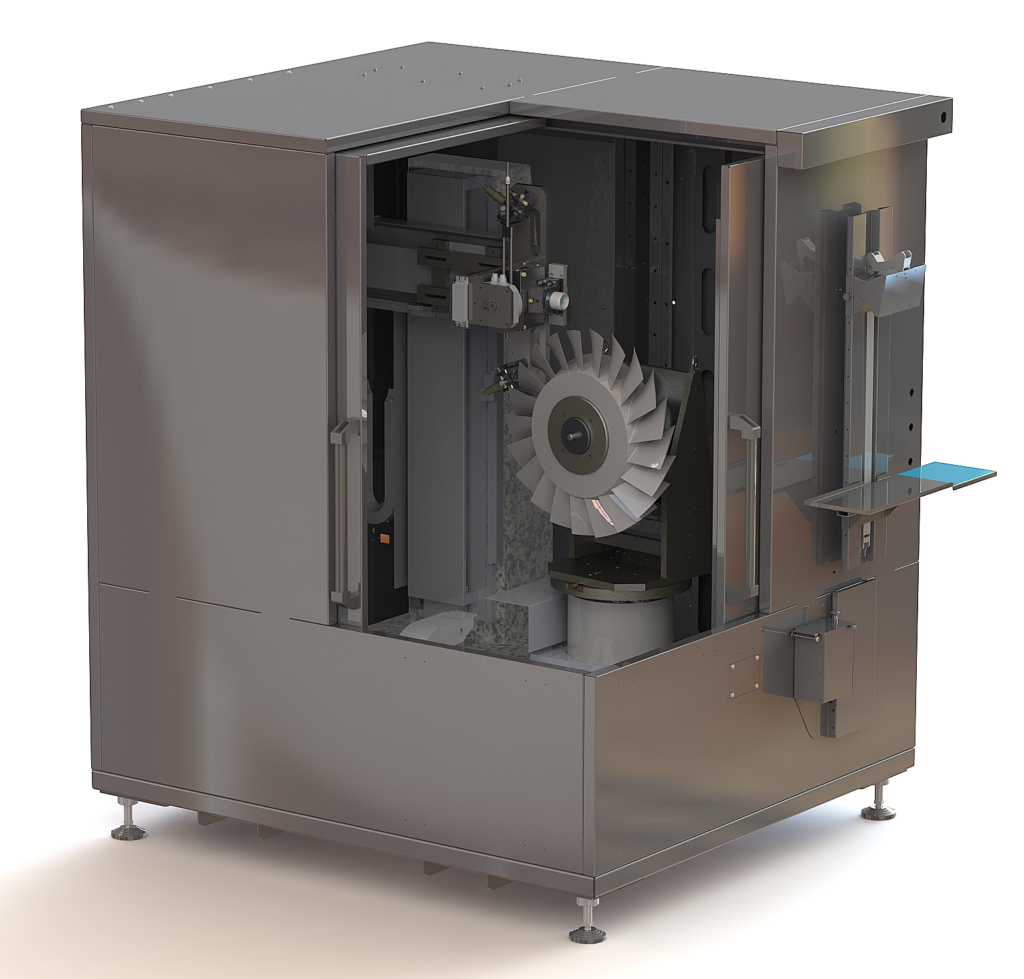

MTL 3D’s Blazer system consolidates all inspection tasks into a single, automated process:

- Non-Contact and High-Speed: Optical scanning replaces manual probes, ensuring consistent and repeatable results.

- Comprehensive Coverage: Inspects all critical areas—airfoils, ring features, fillets, and edges—without manual replicas or visual checks.

- Short Cycle Times: Reduces inspection time to 120–180 minutes, requiring only one operator.

| Aspect | Conventional Methods | MTL 3D’s Blazer System |

|---|---|---|

| Inspection Time | 8–10 hours | 120–180 minutes |

| Operators Required | 3–4 | 1 |

| Accuracy | Operator-dependent | Repeatable and reliable |

| Reporting | Manual, fragmented | Automated, integrated |

Key Features of MTL 3D’s Inspection Systems

| Feature | Benefit |

|---|---|

| High-Speed Optical Scanning | Rapid and detailed geometric analysis. |

| Multi-Axis Adaptability | Handles intricate and diverse geometries with precision. |

| Real-Time Data Reporting | Enables immediate corrective action and process optimization. |

| Repeatability and Accuracy | Ensures consistent results across production cycles. |

| Fully Automated Workflows | Reduces human intervention and eliminates variability. |

Applications of IBR Inspection and Cluster Inspection

MTL 3D’s inspection systems serve a variety of use cases:

- IBR Geometry Inspection: Verifying airfoil profiles, root structures, and platform dimensions.

- Cluster Inspection: Ensuring alignment and uniformity of blade clusters.

- Post-Manufacturing Quality Assurance: Ensuring compliance with specifications before assembly.

- Process Recommendations: Guiding operations like polishing, grinding, or repair based on precise geometry measurements.

- Dimensional Verification: Ensuring all critical features meet stringent aerospace tolerances.

How MTL 3D Enhances Efficiency

Efficiency is at the core of MTL 3D’s approach. Our systems enable manufacturers to:

- Automate Time-Intensive Tasks: Eliminating the need for multiple stations and operators.

- Reduce Inspection Time: Completing the process in 120–180 minutes, a fraction of the conventional time.

- Improve Quality Assurance: Providing detailed, automated final inspection and quality reports for direct integration into customer databases.

Integration with MTL 3D’s Ecosystem

MTL 3D’s solutions seamlessly integrate into manufacturing workflows, enhancing both precision and efficiency:

- Blazer Systems: Comprehensive geometric analysis and reporting, functioning as a standalone system or integrated within automated workflows.

- MARS Software: Simplifies programming and operation while ensuring reliable data storage and accessibility.

- Automatic Load/Unload Solutions:

- A robotic arm can be integrated as part of the system for loading and unloading parts.

- Enhances workflow efficiency and reduces manual intervention.

- Process Integration: Guides subsequent steps like grinding, polishing, and coating based on inspection results.

Technical Parameters of MTL 3D’s IBR Inspection and Cluster Solutions

| Parameter | Value |

|---|---|

| Maximum Blisk Diameter | 800 mm – This capacity enables the inspection of a wide range of IBR sizes, accommodating various engine designs. |

| Inspection Speed | High-speed optical scanning and data processing |

| Accuracy | Within microns |

| Compatibility | Aero engine IBRs, blade clusters, and similar components |

Final Thoughts

MTL 3D’s Blazer inspection systems represent a significant leap forward in IBR Inspection and cluster inspection. By consolidating multiple steps into a single, automated workflow, we deliver unmatched efficiency and accuracy while reducing costs and operator dependency.

With advanced optical scanning, automated data reporting, and integration-ready systems, MTL 3D sets the standard for modern inspection solutions. Contact us today at www.mtl-3d.com to learn how we can optimize your manufacturing processes.