What’s in This Article

- Introduction to Adaptive Robotic Systems

- What is RoboMate?

- Key Features of RoboMate

- Why Choose RoboMate from MTL 3D?

- Applications of RoboMate

- How RoboMate Enhances Efficiency

- System Units and Stations Customization

- Integrated Blazer Inspection System for Final Quality Control

- Technical Parameters of RoboMate

- Integration with MTL 3D Ecosystem

- Final Thoughts

.

Introduction to Adaptive Robotic Systems

In the rapidly evolving world of advanced manufacturing, adaptive robotic systems are setting new standards for efficiency and precision. These intelligent systems integrate automation, accuracy, and flexibility to efficiently tackle complex industrial tasks.

MTL 3D, with decades of experience in high-precision engineering, presents RoboMate—an advanced adaptive robotic system specifically developed for the grinding and polishing of aero engine blades.

RoboMate is not just another robotic tool; it is a complete solution for manufacturers aiming to enhance quality, reduce processing times, and maintain a competitive edge in today’s demanding industrial environment.

What is RoboMate?

RoboMate is a robotic grinding and polishing system integrated with MTL 3D’s Blazer geometry inspection system, which serves as the master controller of the process.

This complete geometry inspection solution enables a seamless “Inspection-Grinding-Inspection” process, ensuring precision and consistency throughout every production stage. Key highlights include:

- Dynamic Path Topography: Real-time grinding paths are calculated and updated based on live inspection data.

- Final Inspection and Quality Reports: The Blazer system generates comprehensive reports for quality verification and QA needs, removing the requirement for additional standalone quality control tests.

- Dual Functionality: When the grinding system is not in use, the integrated Blazer system can function independently as a standalone unit for geometry inspection.

This unique combination of inspection and process control simplifies workflows and enhances quality assurance.

Key Features of RoboMate

RoboMate combines precision, flexibility, and efficiency through its advanced features:

- Aero Engine Blade Grinding: Precision grinding of blade airfoils, edge profiles, radii, and platform areas.

- Polishing Fillet Radii: Smooth, high-quality finishes on fillet radii and intricate blade contours.

- Post-Forging Finishing: Automated solutions to refine blade surfaces post-manufacturing.

- Surface Smoothness Enhancement: Ensures consistent, high-quality surface finishes for performance-critical parts.

- Complex Geometric Shapes: Adapts seamlessly to intricate blade geometries without manual intervention.

- Inspection-Control Integration: The integrated Blazer system dynamically guides grinding operations and verifies geometry parameters in real time.

- Final Inspection and Quality Reports: Automatically generated reports verify compliance with required tolerances, with results stored in the customer’s database.

- Customizable Stations and Units: MTL 3D tailors the number and type of grinding and polishing stations to customer requirements.

Why Choose RoboMate from MTL 3D?

RoboMate delivers a unique combination of inspection, process automation, and robotic adaptability. Here’s why it stands out:

- Integrated Quality Control: The Blazer system provides Final Inspection and Quality Reports, streamlining the quality verification process.

- Dynamic Real-Time Adjustments: Grinding and polishing processes are defined online, guided by real-time inspection data.

- Uncompromising Results: Full grinding path topography and tool usage are dynamically optimized for accuracy.

- Shorter Cycle Times: Adaptive workflows reduce cycle times while improving consistency.

- Standalone Inspection Capability: Blazer operates independently when the grinding system is not in use, providing additional inspection flexibility.

- Customizable Solutions: Tailored to meet specific blade geometries, station configurations, and production needs.

Applications of RoboMate

RoboMate’s versatility makes it suitable for a range of precision manufacturing needs:

- Aero Engine Blade Grinding:

- Grinding of airfoil surfaces, edge profiles, radii, and platform areas with precision.

- Polishing Fillet Radii:

- Smooth finishes on intricate blade contours and radii.

- Post-Forging Finishing:

- Automated processes to refine dimensions and surface quality after forging.

- Surface Smoothness Enhancement:

- Uniform, high-quality finishes for performance-critical components.

- Complex Geometric Shapes:

- Handles diverse and intricate geometries dynamically without manual adjustments.

How RoboMate Enhances Efficiency

RoboMate’s efficiency is driven by its geometry inspection-driven process and seamless automation:

- Real-Time Path Control: Grinding and polishing trajectories are dynamically defined and updated based on live inspection results.

- Integrated Final Quality Control: The Blazer system validates geometry accuracy and generates Final Inspection and Quality Reports for QC and QA needs.

- Reduced Processing Steps: Combines grinding, polishing, and quality control into a single streamlined workflow.

- Consistent Quality: The closed-loop “Inspection-Grinding-Inspection” cycle ensures repeatable and accurate results.

- Error Elimination: Automating processes minimizes variability and reduces human intervention.

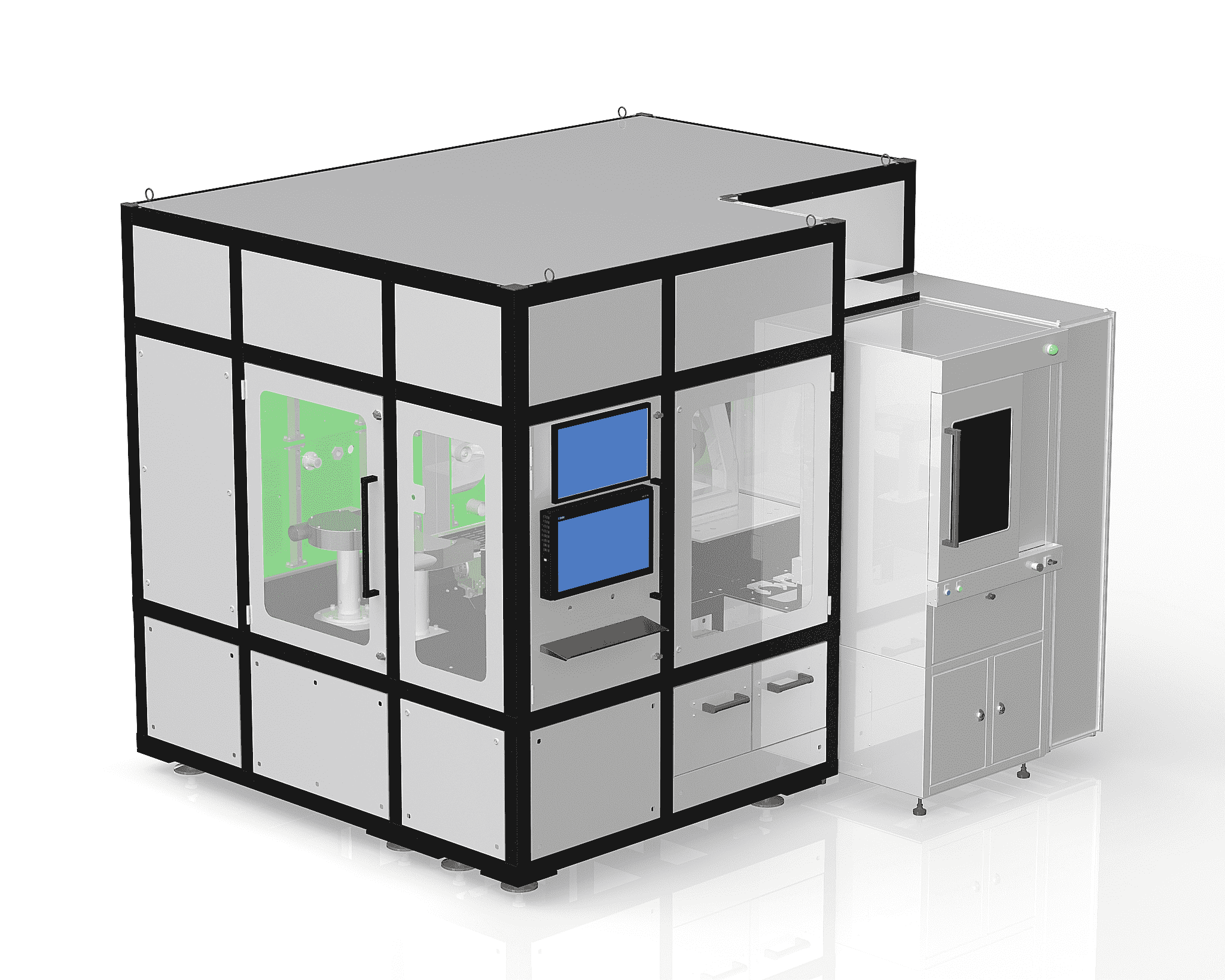

System Units and Stations Customization

At MTL 3D, we recognize that every production facility has unique requirements. RoboMate’s modular design allows full customization of system units, grinding stations, and footprint to meet specific operational needs.

- Number and Type of Stations: Tailored grinding and polishing stations are optimized for part types and production capacities.

- Adapted Dimensions: The system layout integrates smoothly into existing production environments.

This flexibility ensures RoboMate is optimized for your production workflow.

Integrated Blazer Inspection System for Final Quality Control

The Blazer geometry inspection system integrated within RoboMate provides:

- Final Inspection and Quality Reports: Comprehensive reports verify components meet required tolerances and quality standards.

- Automatic Data Storage: Results are automatically stored in the customer database, improving traceability and documentation.

- Standalone Functionality: Blazer can function independently as a geometry inspection unit when the grinding system is not in use.

This integrated approach simplifies the production process while ensuring robust quality control.

Technical Parameters of RoboMate

Parameter | Value |

Maximum Part Height | 350 mm |

Maximum Chord Length | 150 mm |

Maximum Weight (with Fixture) | 30 kg |

Final Thoughts

RoboMate by MTL 3D provides a unified solution for precision grinding, polishing, and quality control of aero engine blades and other critical components. By integrating the Blazer inspection system as the master controller, RoboMate ensures real-time process optimization, generates Final Inspection and Quality Reports, and eliminates the need for redundant QC steps.

With customizable grinding stations, adaptable system dimensions, and seamless data storage, RoboMate helps manufacturers achieve unmatched precision, efficiency, and operational flexibility.

Learn more about RoboMate and discover MTL 3D’s advanced solutions at www.mtl-3d.com. Precision, productivity, and efficiency—built for your needs.

#Automation #Robotics #PrecisionGrinding #Robomate #MTL3D