- Introduction: Transforming Manufacturing with Advanced Engineering Solutions

- Why Advanced Engineering Solutions Matter in Modern Manufacturing

- MTL 3D’s Role in Revolutionizing Quality Assurance

- Industrial Automation Solutions: The Future of Manufacturing Efficiency

- How MTL 3D Supports Defense Manufacturing

- Advancing Aerospace Engineering with MTL 3D

- Heavy Machinery Manufacturing: Reliability at Scale

- Why Choose MTL 3D?

- Conclusion: The Future of Manufacturing with MTL 3D

Introduction: Transforming Manufacturing with Advanced Engineering Solutions

In today’s fast-evolving manufacturing landscape, precision and efficiency are paramount. Companies are under increasing pressure to deliver flawless products while optimizing production processes. At MTL 3D, we specialize in providing advanced engineering solutions that redefine quality control, streamline manufacturing workflows, and ensure the utmost reliability in mission-critical industries. From defense to aerospace, automotive and industrial manufacturing, MTL 3D empowers businesses to achieve unparalleled precision through innovative technologies like industrial automation solutions and 3D inspection systems.

Why Advanced Engineering Solutions Matter in Modern Manufacturing

Modern manufacturing is defined by its need to produce intricate, high-quality components at scale. Mistakes are costly, and industries such as defense and aerospace cannot afford even minor defects. This is where advanced engineering solutions come into play, addressing challenges in design validation, component integrity, and production efficiency.

Key Benefits of Advanced Engineering Solutions:

- Enhanced Precision: Eliminate errors in complex parts and assemblies.

- Reduced Costs: Minimize waste by detecting defects early in production.

- Improved Efficiency: Automate repetitive tasks for faster turnaround times.

- Reliable Quality Assurance: Guarantee compliance with stringent industry standards.

At MTL 3D, we focus on providing these benefits to industries where precision and dependability are not just desired—they’re essential.

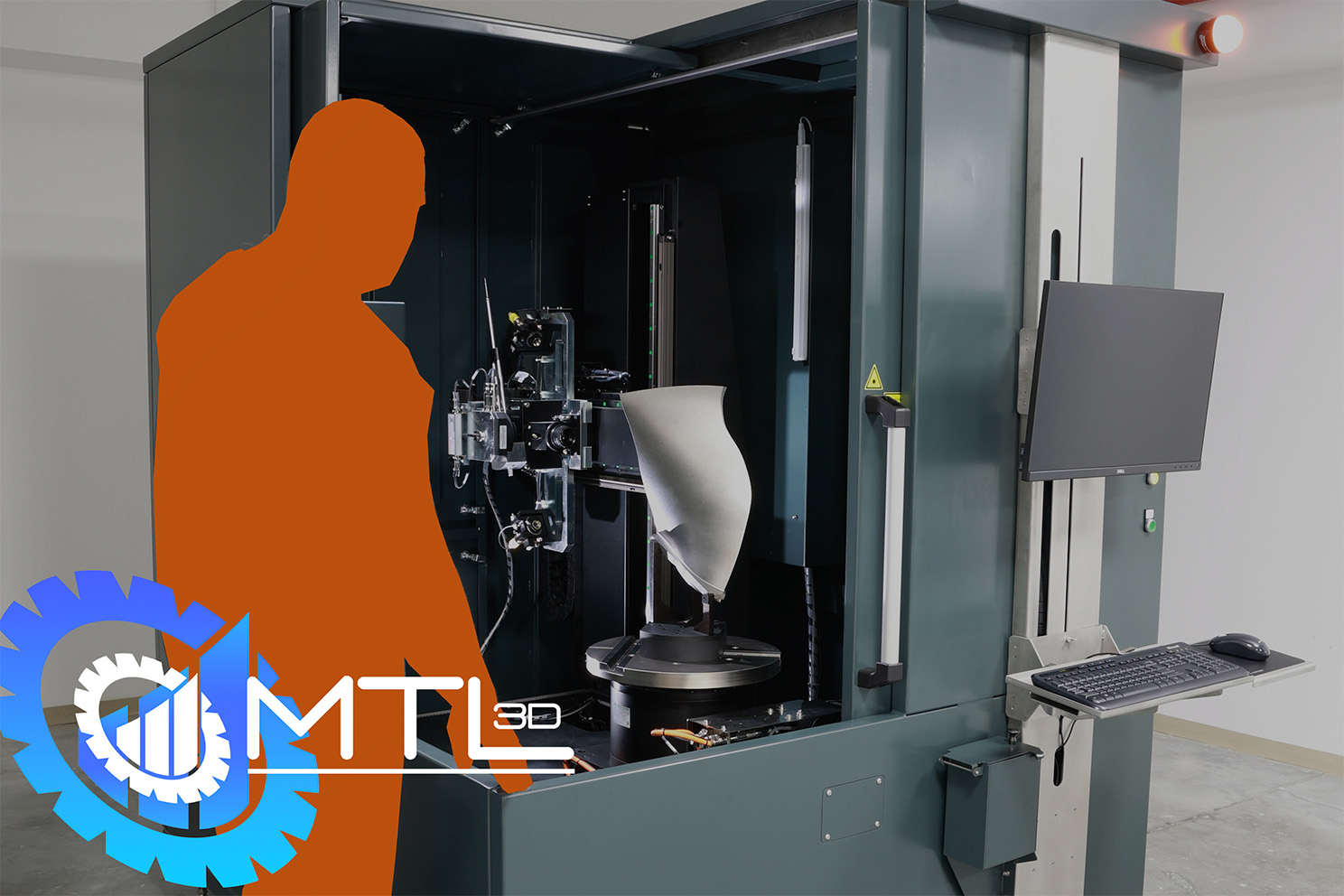

MTL 3D’s Role in Revolutionizing Quality Assurance

At the core of our offerings is the ability to deliver exceptional quality assurance solutions. Through high-speed 3D inspection systems and industrial automation solutions, MTL 3D ensures that every component meets the exacting standards required in defense, aerospace, and other industries.

3D Inspection: Elevating Quality Control Standards

3D inspection is a cornerstone of MTL 3D’s approach to modern manufacturing. Unlike traditional methods that rely on 2D analysis or manual measurements, 3D inspection provides an accurate representation of an object’s geometry, capturing data in three dimensions.

Applications of 3D Inspection in Key Industries:

Defense:

- Ensures the structural integrity of critical components like armored vehicle parts and missile systems.

- Identifies wear and tear in military hardware to extend its operational lifespan.

Aerospace:

- Validates the precision of intricate components such as aero engine blades, IBR’s, clusters etc.

- Detects defects that could compromise the safety or performance of aircraft.

Automotive:

- Verifies the accuracy and alignment of critical parts such as engine components, transmissions, and braking systems.

- Ensures defect-free production of high-precision parts, enhancing vehicle safety and performance.

By integrating 3D inspection into manufacturing workflows, MTL 3D helps businesses achieve consistent quality and eliminate costly errors.

Industrial Automation Solutions: The Future of Manufacturing Efficiency

In addition to 3D inspection, MTL 3D specializes in industrial automation solutions that streamline production processes and reduce human error. Automation plays a pivotal role in modern manufacturing, allowing companies to achieve faster throughput without sacrificing quality.

Benefits of MTL 3D’s Industrial Automation Solutions:

- Increased Productivity: Automates repetitive tasks, freeing up human resources for more strategic roles.

- Higher Accuracy: Uses precise machinery and robotics to maintain consistent output.

- Scalability: Adapts to varying production volumes without requiring significant reconfiguration.

- Cost Savings: Reduces labor costs while minimizing waste through more efficient processes.

Applications of Industrial Automation in Key Industries:

Defense:

- Automates geometry inspection and sorting for critical components like vehicle-mounted systems and missile parts.

- Implements coating and marking systems to streamline production workflows and enhance process efficiency.

Aerospace:

- Specializes in non-contact geometry inspection of complex components, including aero engine blades and IBRs, ensuring compliance with strict standards.

- Provides automatic sorting solutions based on inspection results to guide subsequent manufacturing steps, such as grinding or repair.

Automotive:

- Offers geometry inspection and process automation for components like engines, transmissions, and precision parts.

- Integrates marking systems to print measured deviations directly on inspected parts, enabling quicker and more accurate corrections.

How MTL 3D Supports Defense Manufacturing

In the defense sector, reliability and accuracy are paramount. Any failure in manufacturing can lead to catastrophic outcomes. MTL 3D provides advanced engineering solutions tailored to the unique needs of defense contractors and manufacturers.

Key Offerings for Defense:

- Structural Analysis: Verifies the integrity of armored components and vehicle systems.

- Precision Assembly: Ensures accurate fitment of components for mission-critical applications.

- Lifecycle Management: Uses 3D inspection to monitor wear and schedule maintenance for defense equipment.

By ensuring that all components meet the highest standards of quality, MTL 3D helps defense contractors deliver reliable solutions for national security.

Advancing Aerospace Engineering with MTL 3D

The aerospace industry requires some of the most demanding quality control measures in manufacturing. A single defect can compromise safety, performance, or regulatory compliance. MTL 3D leverages its expertise in advanced engineering solutions to support the aerospace sector’s need for precision and reliability.

How MTL 3D Drives Aerospace Innovation:

- Component Validation: Inspects critical parts like aero engine blades, landing gear, and engine components.

- Dimensional Accuracy Assurance: Uses 3D inspection to ensure all components meet strict aerospace dimensional and geometric tolerances.

- Seamless Integration: Ensures that all components fit together perfectly during assembly, reducing post-production adjustments.

MTL 3D’s solutions enable aerospace manufacturers to produce safe, efficient, and reliable aircraft components at scale.

Industrial Manufacturing: Reliability at Scale

Manufacturers often face the challenge of achieving precision and consistency in the production of complex components. MTL 3D’s advanced engineering solutions address these challenges by leveraging non-contact geometry inspection and process automation to streamline production workflows and ensure high-quality results.

Applications in Industrial Manufacturing:

Geometry Inspection:

- Provides high-precision non-contact 3D inspection to verify complex component dimensions and tolerances.

- Ensures components meet industry standards and are compatible with downstream production processes.

Process Automation:

- Implements automated workflows for tasks such as dimensional checks and quality assurance to enhance production efficiency.

- Reduces production bottlenecks by integrating reliable inspection systems into manufacturing lines.

Dimensional Analysis:

- Offers detailed analysis of parts to ensure they meet exacting specifications and support operational reliability.

- Detects potential deviations early, minimizing rework and optimizing overall manufacturing processes.

Through its tailored solutions, MTL 3D enables manufacturers in industries such as aerospace, defense, and automotive to achieve consistent quality, optimize production workflows, and reduce operational costs.

Why Choose MTL 3D?

At MTL 3D, we don’t just offer technology—we provide solutions that drive results. Our approach is centered on understanding the unique challenges of each client and delivering tailored systems that improve precision, efficiency, and overall performance.

What Sets Us Apart:

- Expertise: Decades of experience in advanced manufacturing technologies.

- Customization: Solutions tailored to the specific needs of defense, aerospace, and industrial manufacturing.

- Reliability: Cutting-edge tools and processes that ensure consistent, high-quality output.

- Customer Support: Comprehensive training and support to help clients maximize their investment in MTL 3D solutions.

Conclusion: The Future of Manufacturing with MTL 3D

As manufacturing continues to evolve, the need for advanced engineering solutions becomes increasingly critical. At MTL 3D, we’re proud to be a trusted partner for businesses in defense, aerospace, and industrial manufacturing, delivering innovative technologies that redefine precision and efficiency.

From 3D inspection to industrial automation solutions, our offerings ensure that manufacturers stay ahead of the curve while maintaining the highest quality standards. Ready to take your production processes to the next level? Contact us today at www.MTL-3D.com/contact to learn how MTL 3D can help transform your manufacturing operations.