Table of Contents

- Introduction to 3D Inspection

- What is 3D Inspection?

- The Difference Between 2D and 3D Inspection

- Types of 3D Inspection Technologies

- Applications of 3D Inspection in Different Industries

- Advantages of 3D Inspection

- Challenges and Future of 3D Inspection

- MTL 3D: Expertise in Turbine Blade Inspection

- Case Studies: Success Stories with 3D Inspection

- Conclusion: The Future of 3D Inspection

Introduction to 3D Inspection

Precision and quality have become the cornerstone of modern manufacturing, and 3D inspection has emerged as a revolutionary technology addressing these demands. By capturing comprehensive three-dimensional data, it offers unmatched accuracy and efficiency, redefining quality control across industries.

At MTL 3D, inspection is at the heart of our expertise. With decades of experience and a proven track record, we deliver advanced solutions like Blazer inspection systems and MARS software, designed specifically to meet the stringent requirements of global manufacturers such as Pratt & Whitney, Rolls Royce, Snecma, MTU, and GE.

What is 3D Inspection?

3D inspection utilizes scanning technologies to analyze and measure complex components in three dimensions. This approach provides a complete view of parts, capturing depth and volume, and allowing for more thorough defect detection compared to traditional 2D methods.

Key Capabilities:

- Detailed 3D Models – Comprehensive data collection for accurate analysis.

- Dimensional Measurements – Measures heights, widths, and volumes to ensure compliance.

- Surface Defect Detection – Identifies imperfections that may impact product performance.

2D vs. 3D Inspection – Key Differences

Feature | 2D Inspection | 3D Inspection |

Dimensional Scope | Length & Width | Height, Depth & Volume |

Accuracy | Surface-level | Full dimensional coverage |

Defect Detection | Limited | Internal and external flaw detection |

Speed | Slower, manual-intensive | Automated, faster inspection |

- 3D inspection reduces errors and provides manufacturers with better control over product quality.

- By providing deeper insights, 3D inspection delivers greater accuracy and reliability for modern manufacturing needs.

Key Features of 3D Inspection

- Creates precise 3D models for analysis, based on captured scan data.

- Measures dimensions like height, width, depth, and volume.

- Detects minute defects and deviations.

These capabilities make 3D inspection an essential tool for industries requiring high precision and reliability.

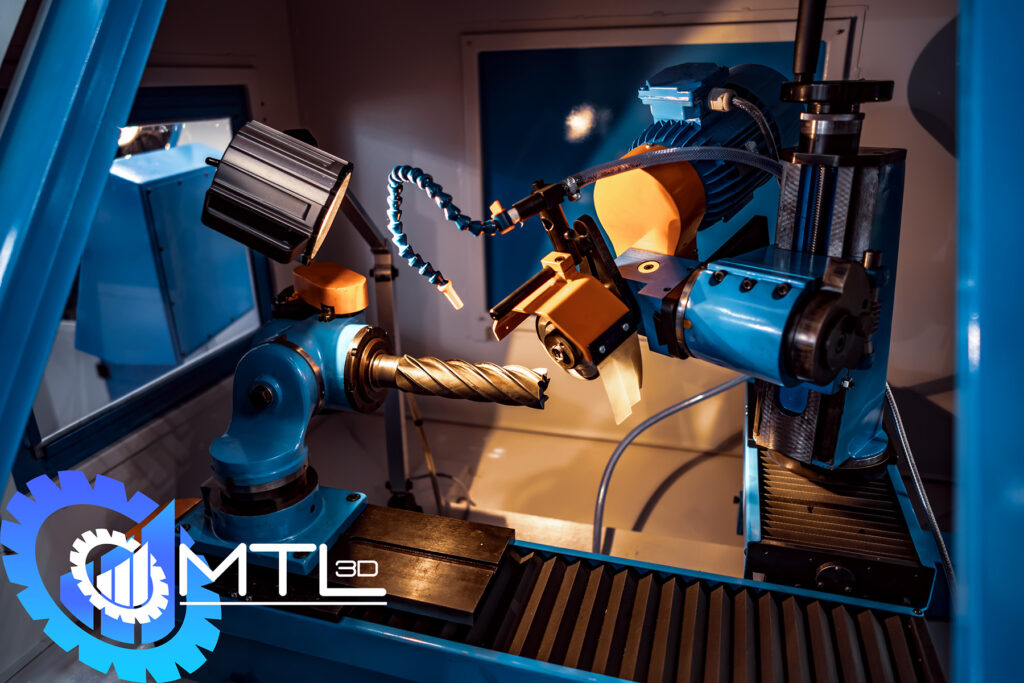

Types of 3D Inspection Technologies

3D inspection employs various technologies to suit different applications and industries. Here are some of the most common methods:

- Laser Scanning

- Captures detailed point cloud data for accurate measurements.

- Structured Light Scanning

- Projects light patterns onto surfaces to generate 3D profiles.

- Automated 3D Inspection Systems

- Inline systems capable of high-speed inspections during production.

MTL 3D’s Blazer series incorporates laser scanning for precise, non-contact measurements, enhancing quality control processes.

Applications of 3D Inspection in Different Industries

3D inspection has proven invaluable across a wide range of industries, helping to ensure quality, efficiency, and compliance. Below are some of the key applications:

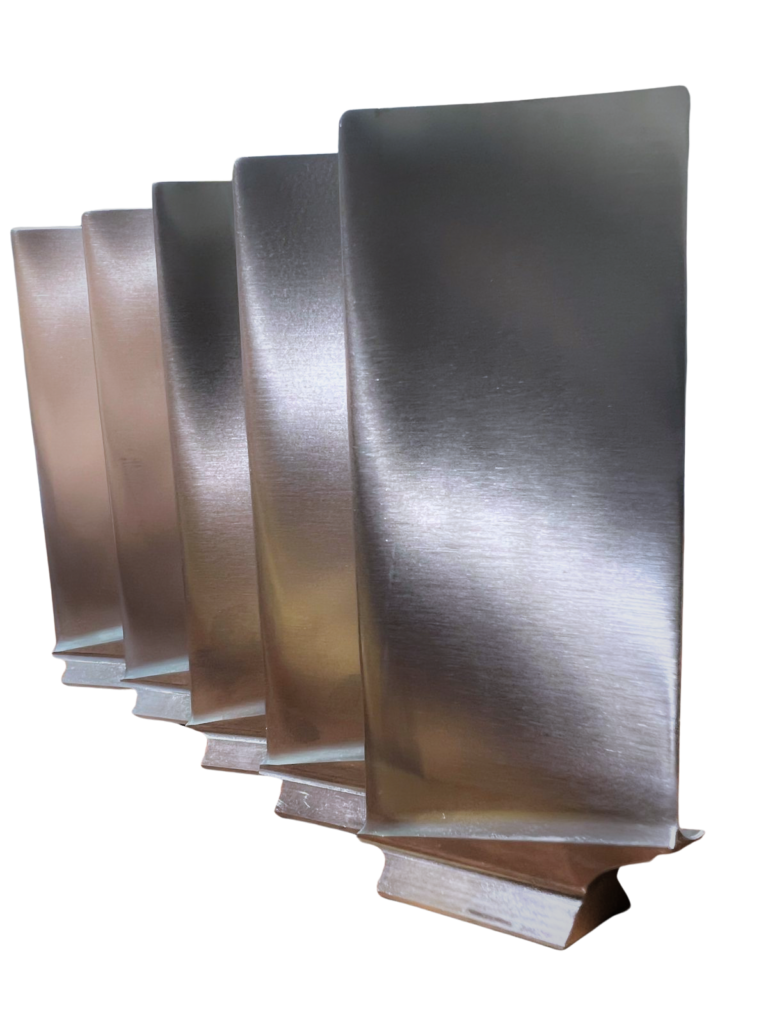

1. Aerospace

- Turbine Blade Inspection: Ensures compliance with vendor-specific requirements like those of Pratt & Whitney and Rolls Royce.

- Surface Analysis: Detects geometry defects and profile irregularities.

2. Automotive

- Prototype and Production Validation: Compares actual scan data of components to nominal CAD models to detect defects and deviations.

- Alignment and Fit Verification: Ensures parts align correctly within assemblies to meet end-of-line quality standards.

3. Defense

- Inspects military hardware for structural soundness.

- Evaluates advanced weaponry for compliance with strict specifications.

4. Energy & Heavy Industry

- Dimensional Inspection: Ensures structural integrity of medium-sized components.

- Automated Welding Checks: Monitors weld quality for consistency.

- Process Optimization: Improves efficiency through real-time inspection feedback.

5. Manufacturing

- Data-to-Nominal Comparison: Verifies production parts by comparing scanned data to their nominal CAD models, ensuring compliance with design specifications.

- Confirms assembly alignment and tolerances.

Advantages of 3D Inspection

1. Superior Accuracy:

- Detects deviations smaller than 0.01 mm.

- Ensures compliance with strict specifications.

2. Enhanced Efficiency:

- Real-time feedback reduces production delays.

- Streamlines high-volume manufacturing.

3. Cost Reduction:

- Prevents rework and downtime.

- Reduces labor-intensive inspection processes.

4. Versatility:

- Handles diverse materials and complex geometries.

- Adapts to various industries and applications.

Challenges and Future of 3D Inspection

While 3D inspection offers numerous benefits, it is not without its challenges:

Current Challenges

- Initial Costs: Advanced inspection systems require upfront investment.

- Skilled Operators: Effective use requires trained personnel for setup and interpretation.

Future Opportunities

- Broader Adoption: Expanded use in emerging industries like renewable energy and medical devices.

- AI and Automation – Systems capable of predicting defects and automating corrections.

- Smart Factories – Integration with Industry 4.0 for improved workflow automation.

- Portable Solutions – Mobile units for on-site inspections in remote or industrial environments.

The future of 3D inspection is driven by innovation, making it more accessible and versatile for various applications.

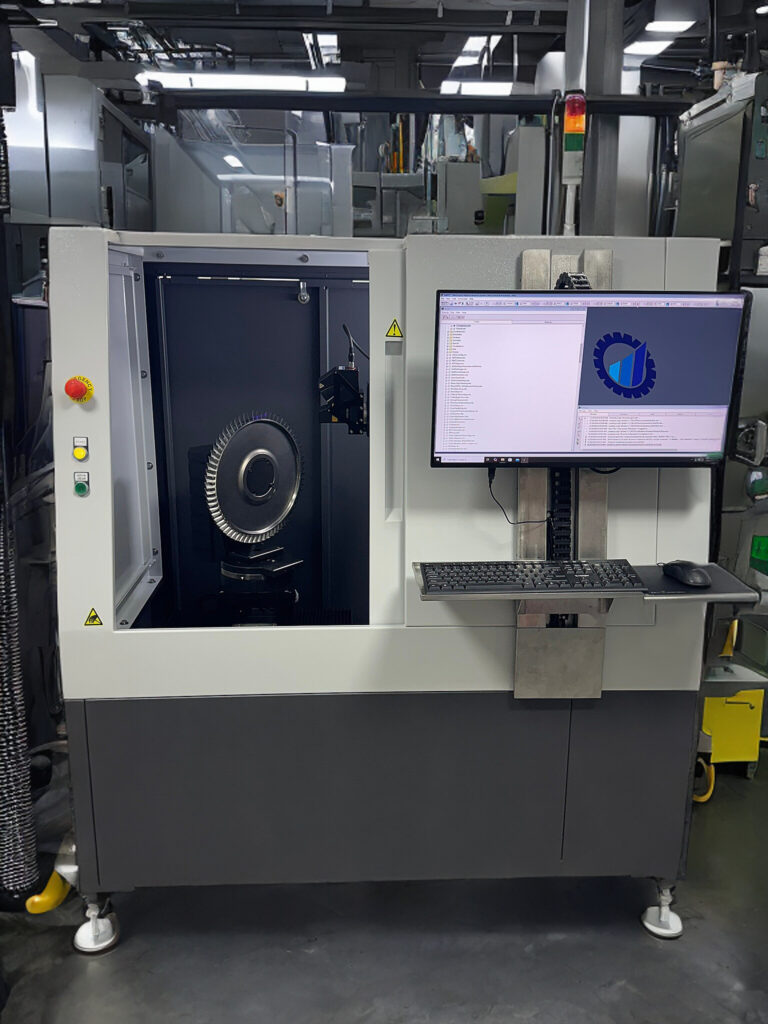

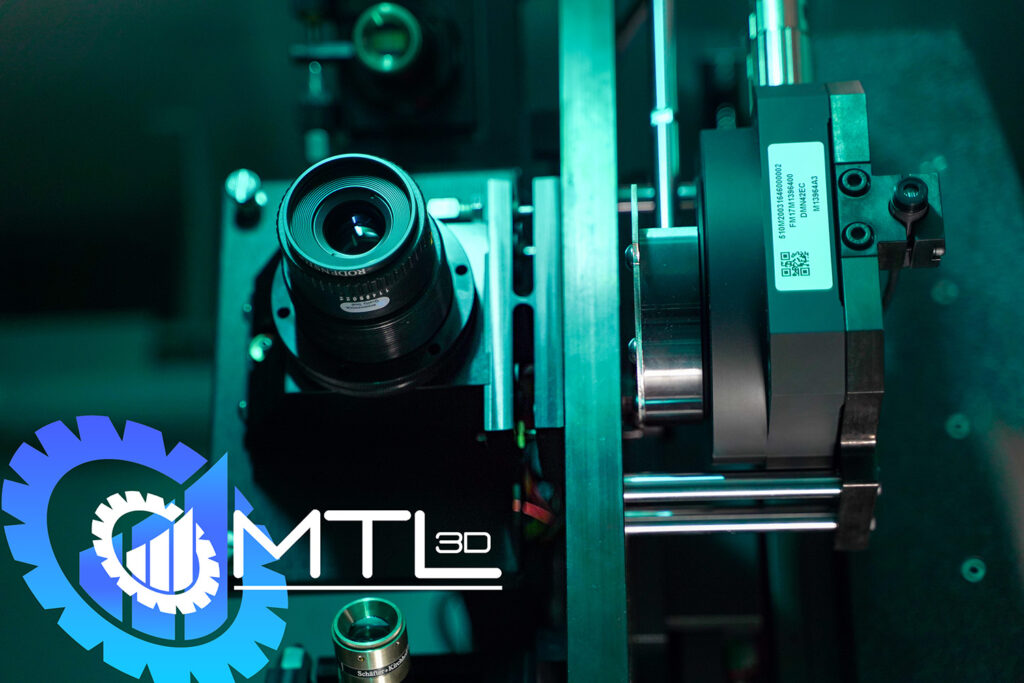

MTL 3D’s Expertise in Precision Inspection

At MTL 3D, inspection is an integral part of quality assurance. Our Blazer series and MARS software provide manufacturers with fast, accurate inspections, reducing errors and ensuring consistent output across production lines.

Blazer Inspection Systems

- Non-Contact Inspection: Ensures precision without damaging parts.

- Short Cycle Times: Optimized for high-speed production environments.

- Proven Reliability: Trusted by Pratt & Whitney and GE

MARS Software

- Nominal Data Comparison: Allows seamless comparison of scan data to nominal CAD models, ensuring deviations are easily identified and corrected.

- Vendor-Specific Presets: Select parameters and methods tailored to each manufacturer.

- Customizable Settings: Adjust parameters independently to meet unique requirements.

Case Studies: Success Stories with 3D Inspection

Case Study 1: Aviation

A global aerospace manufacturer integrated MTL 3D’s Blazer systems for turbine blade inspection. The implementation resulted in a 60% to 75% reduction in inspection times, transforming the efficiency of their quality control processes. By meeting the precise requirements of manufacturers like Pratt & Whitney, Rolls Royce, and GE, the system ensured enhanced compliance with strict regulatory and vendor-specific standards.

Case Study 2 Energy Sector:

MTL 3D developed a custom solution for inspecting turbine blade coatings at various stages of production. This ensured uniform application and improved material integrity, resulting in enhanced performance and longer component lifespans.

Case Study 3: Defense

A defense contractor leveraged MTL 3D’s inspection systems to evaluate critical weaponry components. The integration achieved near-zero defect rates, ensuring reliability in mission-critical applications and reducing maintenance downtime significantly.

Conclusion: The Future of 3D Inspection

3D inspection is revolutionizing quality control by offering precision, efficiency, and adaptability. With solutions like Blazer inspection systems and MARS software, MTL 3D empowers industries to meet and exceed the highest quality standards.

Ready to transform your inspection processes? Contact MTL 3D today to explore how our expertise can elevate your operations