For over 25 years, MTL 3D has been at the forefront of complex geometry inspection solutions, specializing in Aero Engine blade inspections for some of the world’s most demanding manufacturers, including Pratt & Whitney, Rolls Royce, Snecma, MTU, and GE.

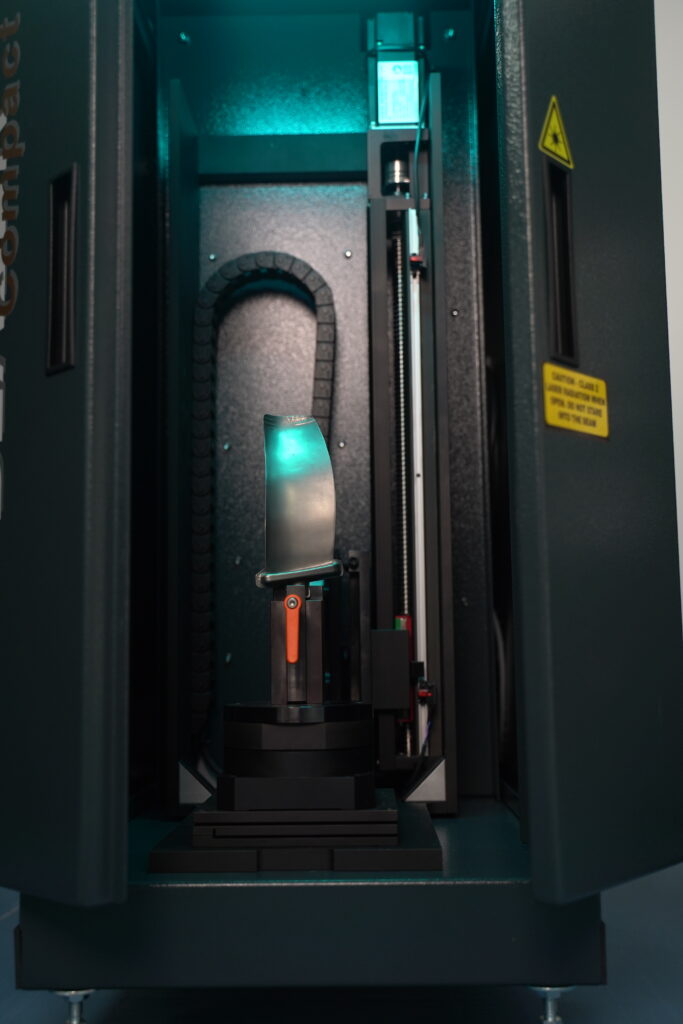

Blazer Inspection Systems: A trusted product line delivering non-contact, high-precision measurements and recognized for having one of the shortest inspection cycle times in the industry. These systems are engineered to meet and exceed stringent requirements for turbine blade manufacturers.

MARS Software: Advanced, user-friendly software that allows for vendor-specific preset configurations or fully customizable inspection parameters, ensuring maximum adaptability and unmatched accuracy.

Our extensive expertise in blade inspection techniques enables us to provide repeatable and correlative inspection services, ensuring that results are consistent and reliable across all customer applications.

By combining decades of experience, innovative hardware, and tailored software, MTL 3D offers precision, reliability, and efficiency to optimize quality assurance processes and ensure compliance with exacting standards.

At MTL 3D, we specialize in delivering advanced robotic systems designed to meet the unique requirements of industries worldwide. By integrating 3D inspection technology, our solutions enhance operational efficiency and support seamless production workflows.

Our advanced robotic systems prioritize automation, adaptability, and reliability, enabling businesses to optimize operations and reduce costs. From tackling complex manufacturing challenges to improving workflow consistency, our solutions are designed for practicality and durability.

With a focus on innovation and sustainability, MTL 3D supports industries with technologies tailored to meet the demands of modern manufacturing.

Transform your operations with our industrial automation solutions—designed to streamline processes, increase efficiency, and reduce costs. From robotic systems to smart manufacturing, our cutting-edge technologies ensure precision and reliability at every step.

MTL 3D revolutionizes robotic automation with its RoboMate and Blazer systems. RoboMate specializes in precise grinding and polishing of aero engine blades, seamlessly integrating with Blazer’s advanced optical measuring technology for accurate geometric analysis. The Blazer system delivers high-speed, non-contact inspections of Aero Engine Blade parameters, ensuring precision and efficiency. Together, these systems optimize workflows, enhance quality control, and boost productivity in complex industrial applications.

In today’s fast-paced manufacturing landscape, precision, efficiency, and reliability are non-negotiable. MTL 3D understands this dynamic, which is why our cutting-edge optical inspection solutions are designed to transform your quality control processes and help your business achieve unmatched operational excellence.

With hundreds of systems installed worldwide, and more than five hundred successful turn key projects completed. MTL 3D continues to excel and thrive as we build relationships with manufacturers, advanced robotic companies and technology forces from around the globe.

Ready to transform challenges into solutions? Dive into our curated Engineering Solutions Articles & Resources to get started